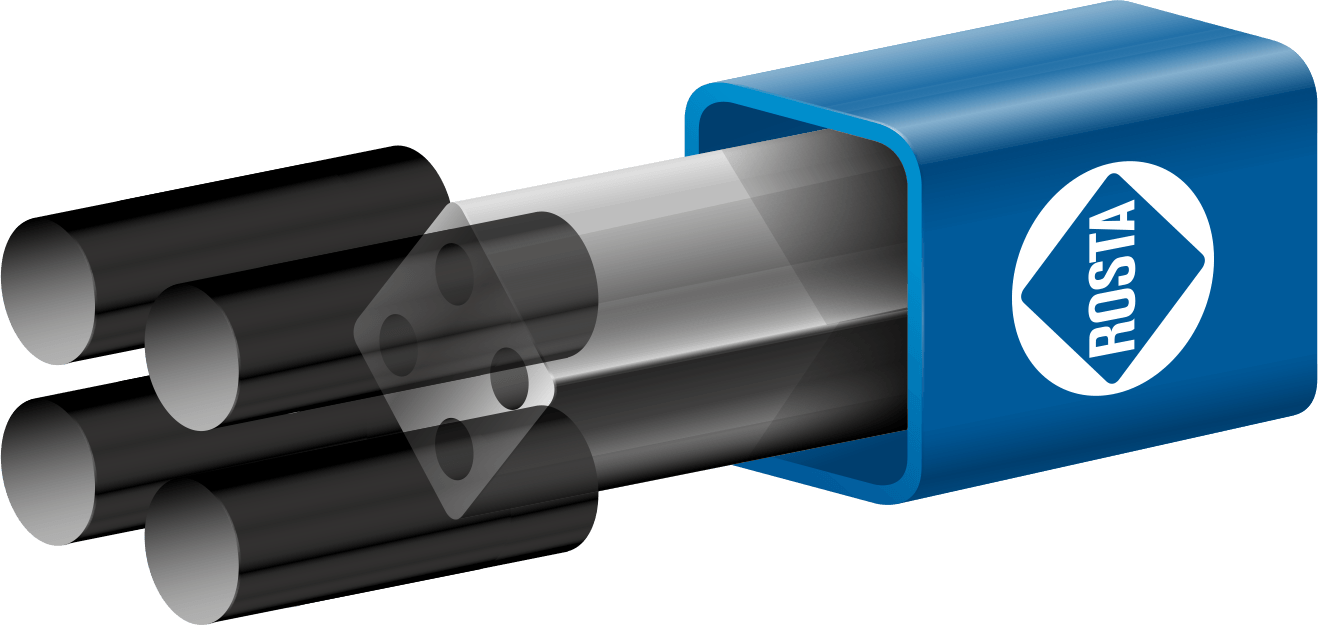

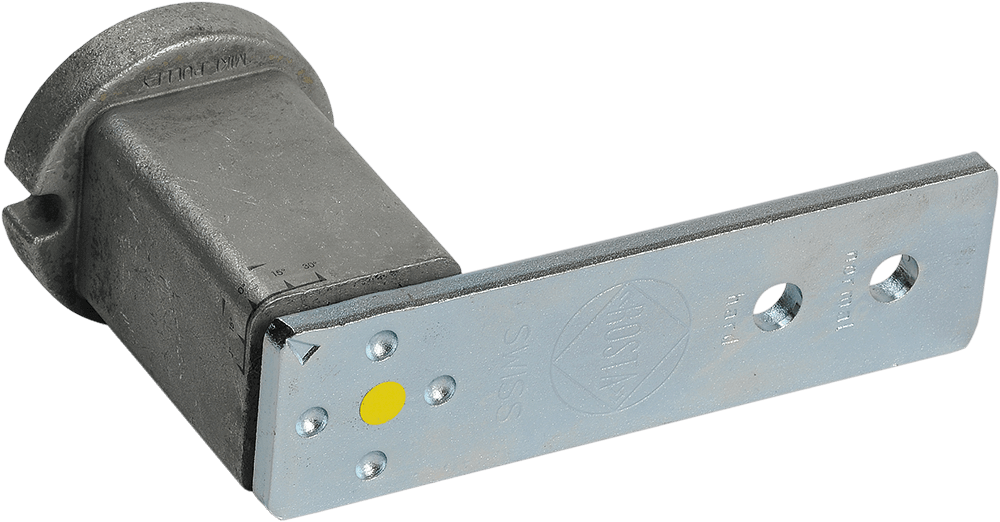

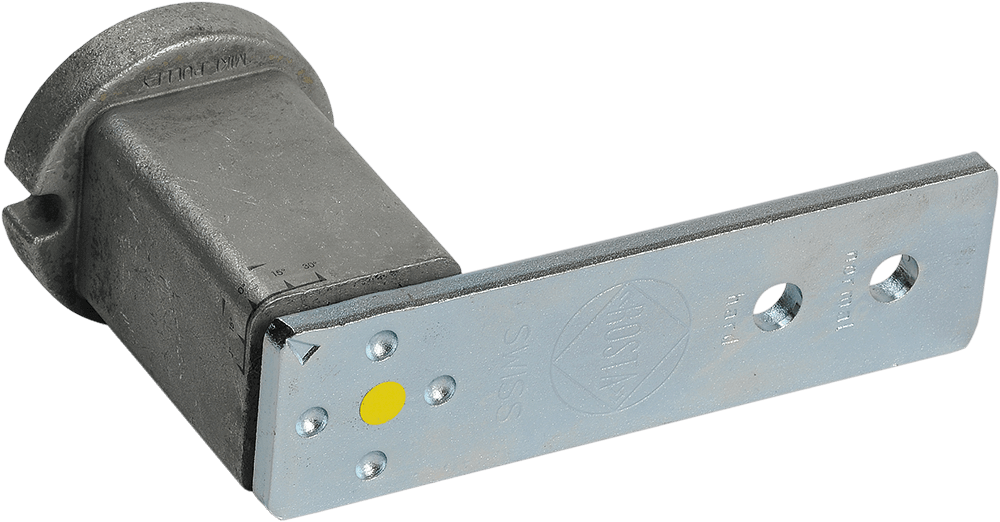

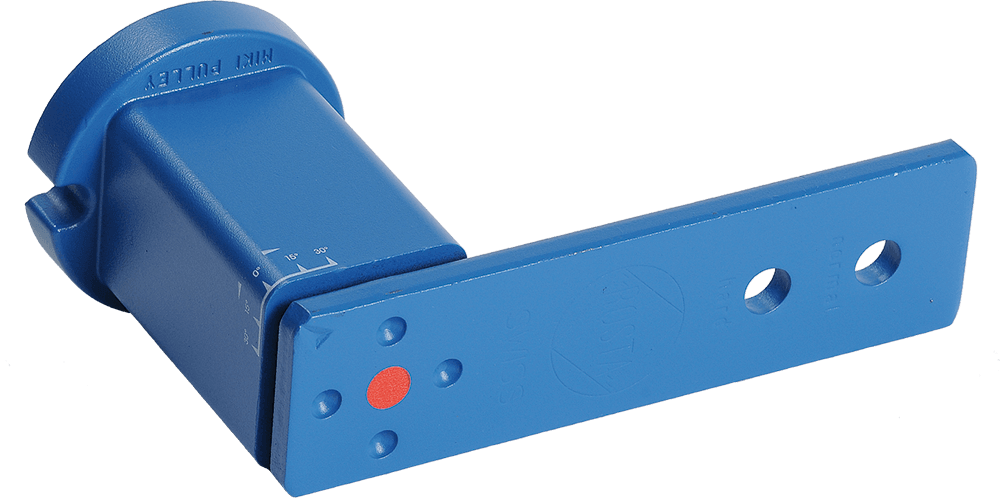

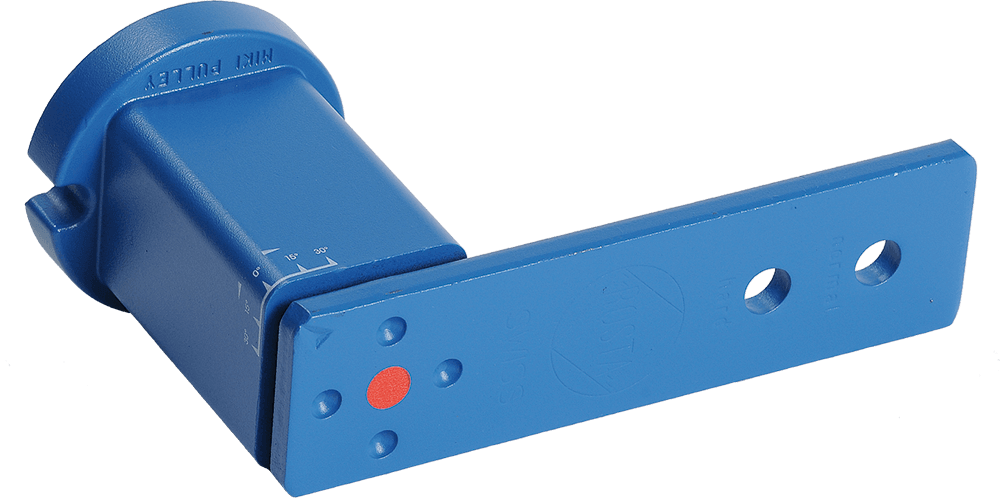

Durable outer housing.

Precision crafted inner section

featuring multiple connection options.

Specialized, high-performance elastomer compound cords.

电机机型

电机框架尺寸

| 最大电机转速 | 最大电机功率 | ROSTA电机底座 |

|---|---|---|

| 1000 RPM | 0.75 kW | ROSTA MB 27 x 120 |

注释

可提供更大型机座,详情请联系ROSTA。

Unit selector

皮带类型

小滑轮直径

皮带数量

| 初始静态皮带偏转力 | 最小张紧力 | ROSTA建议张紧力 |

|---|---|---|

| 22 N/belt | 22 N | 44 N |

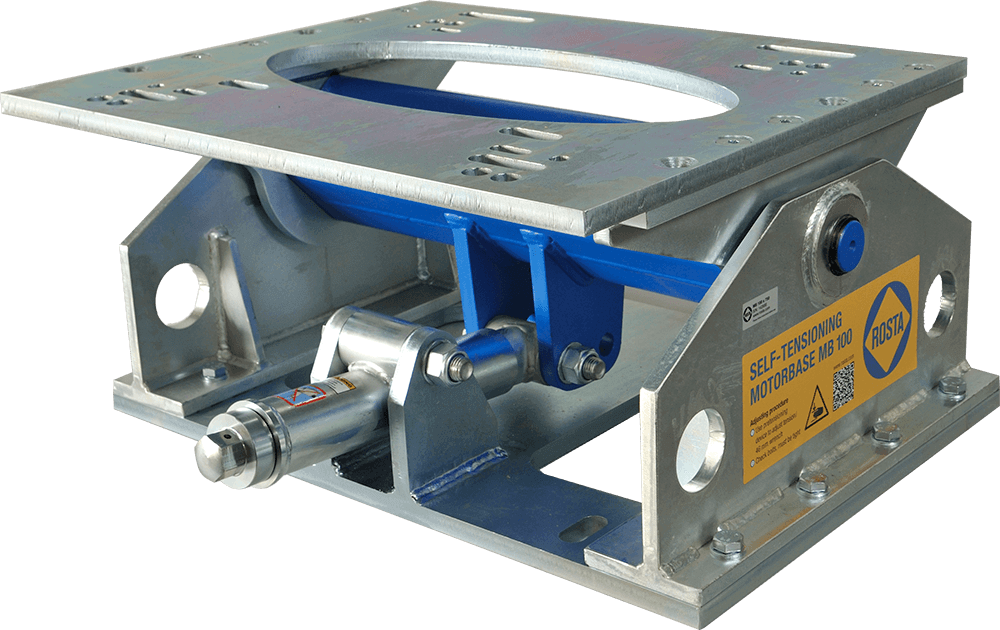

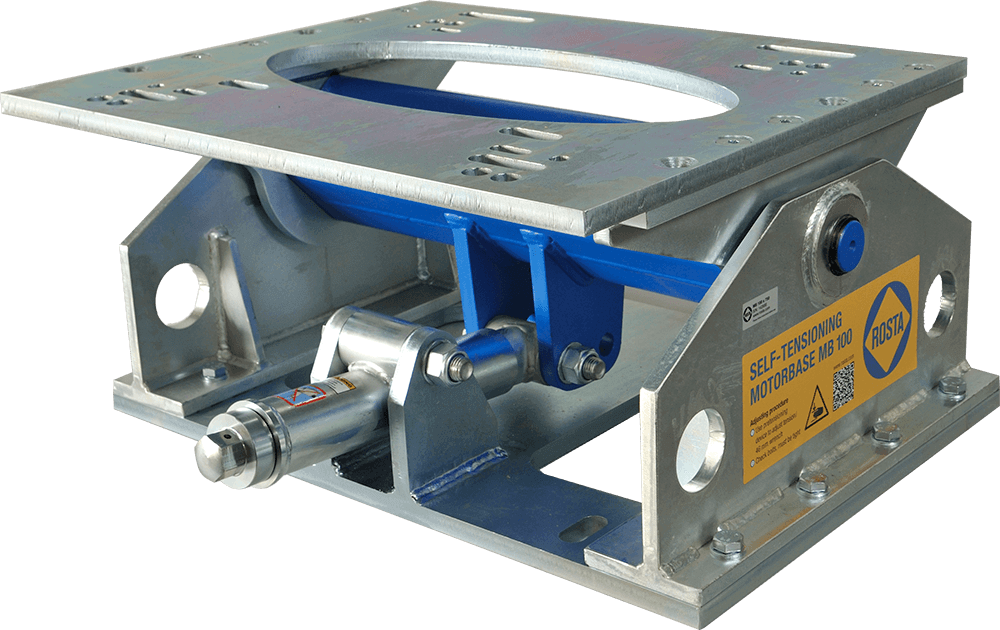

MB 100型电机弹性张紧底座适用的电机功率在90KW-250KW之间(IEC标准电机规格型号315M至355L/NEMA标准电机规格型号447T至586/7)

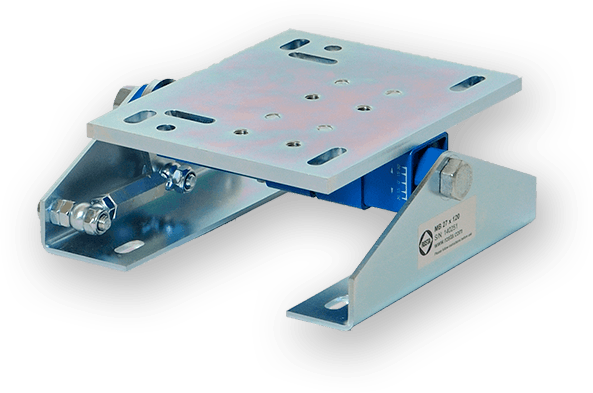

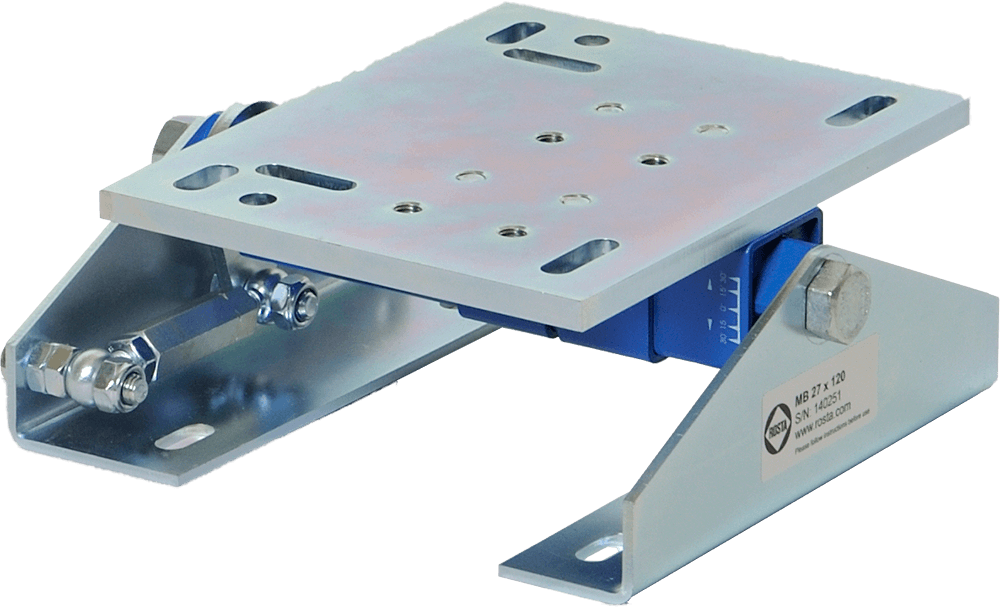

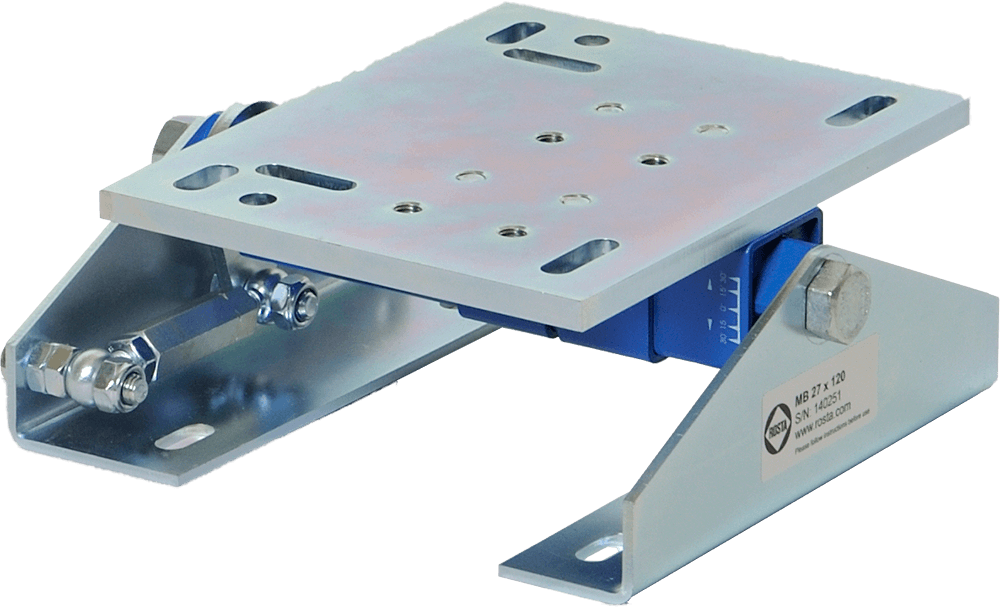

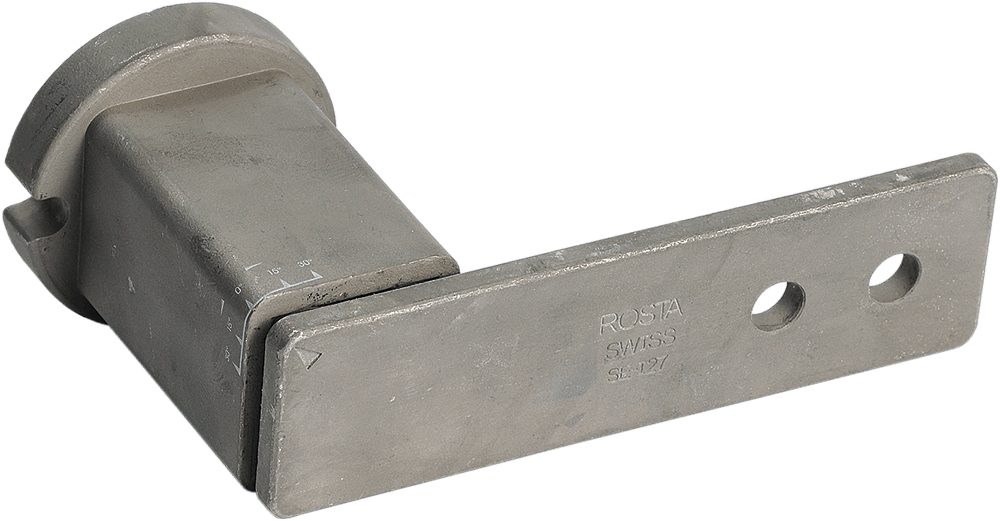

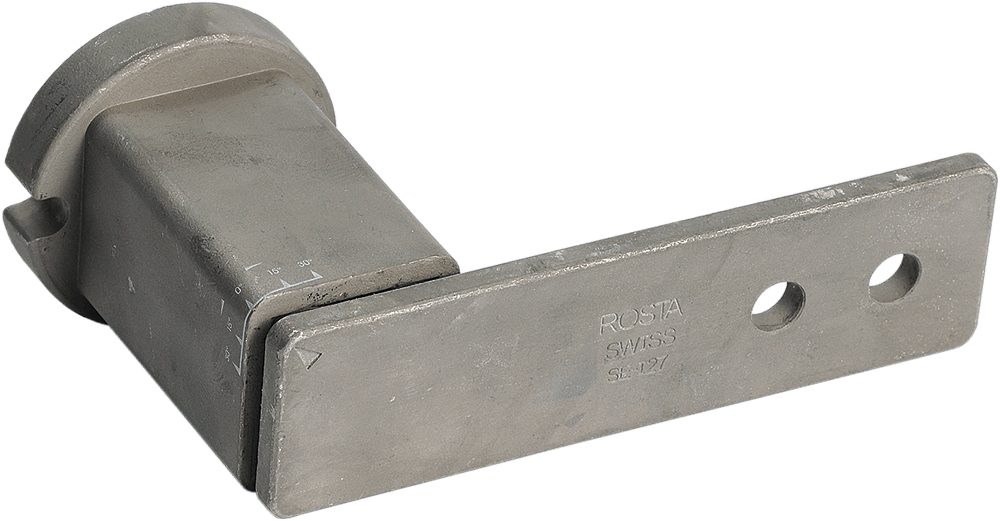

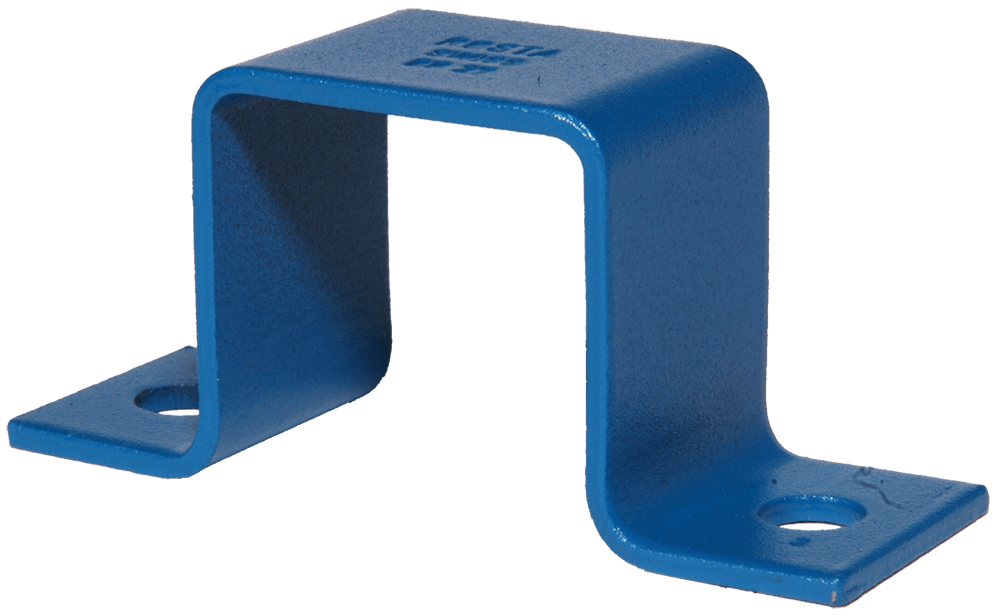

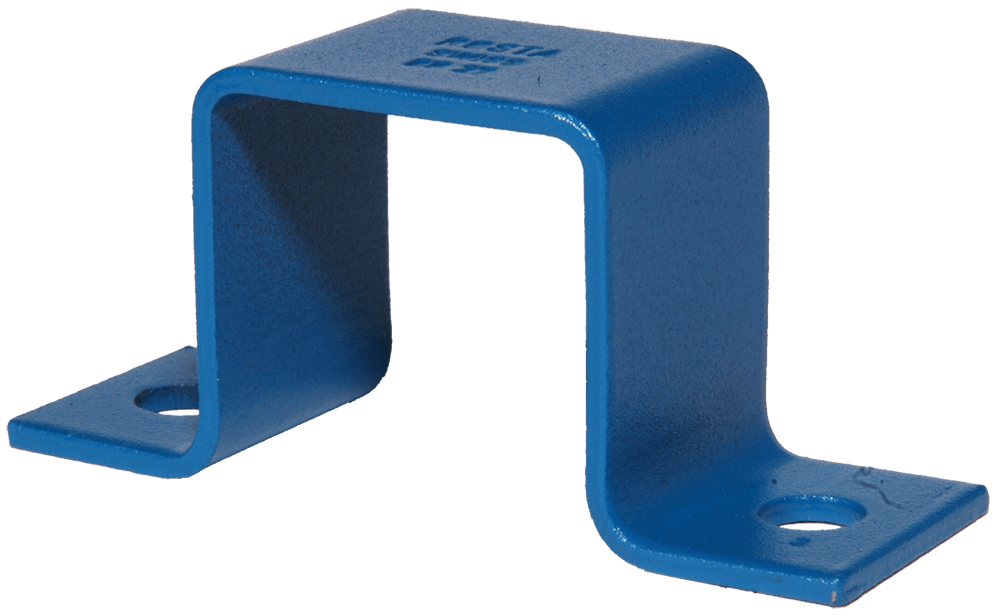

MB 27型电机弹性张紧底座适用的电机功率在0.75KW-4KW之间(IEC标准电机规格型号90S至112M),这是一款标准化的小型电机底座。

MB 38型ROSTA电机弹性张紧底座适用于电机功率3KW-15KW(电机规格型号从132S至160L),该型号结构紧凑,操作方便,可立即安装且经济实惠。

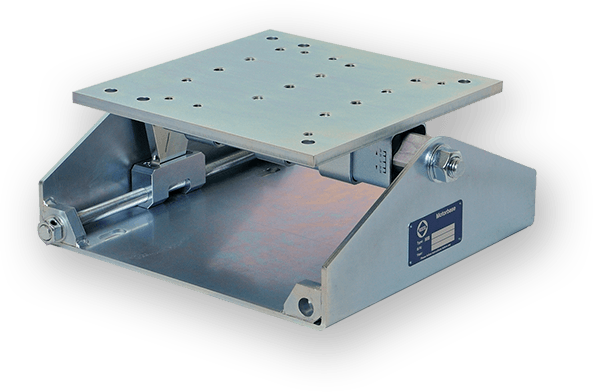

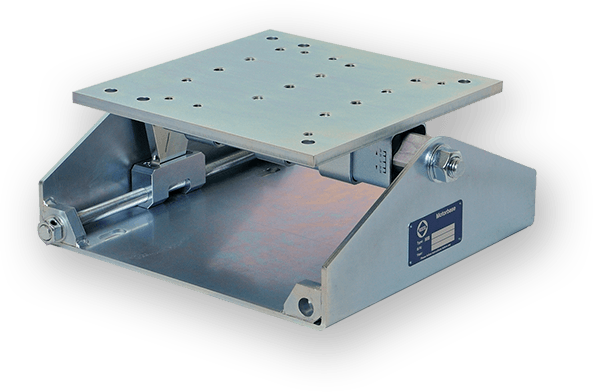

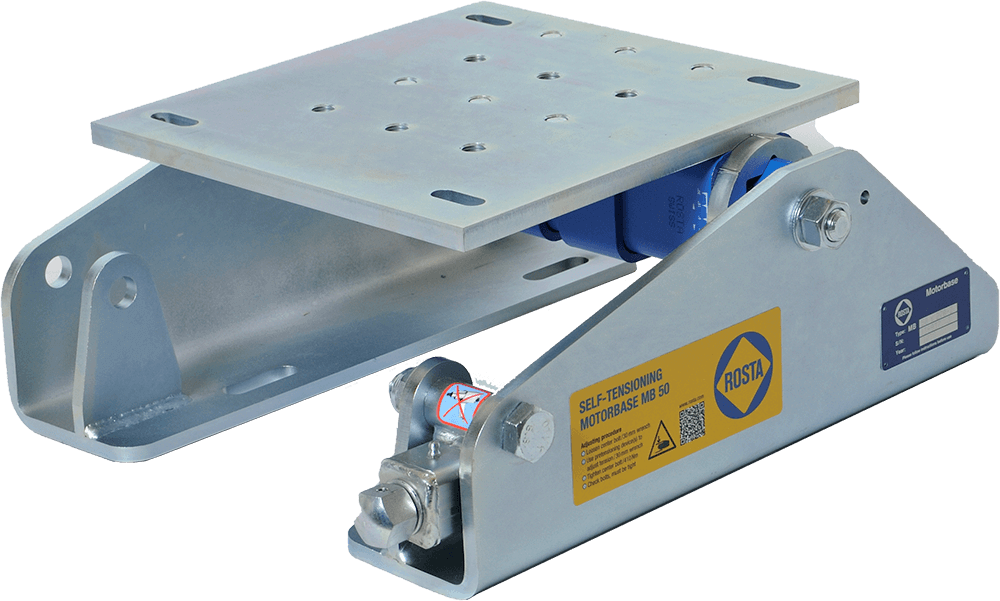

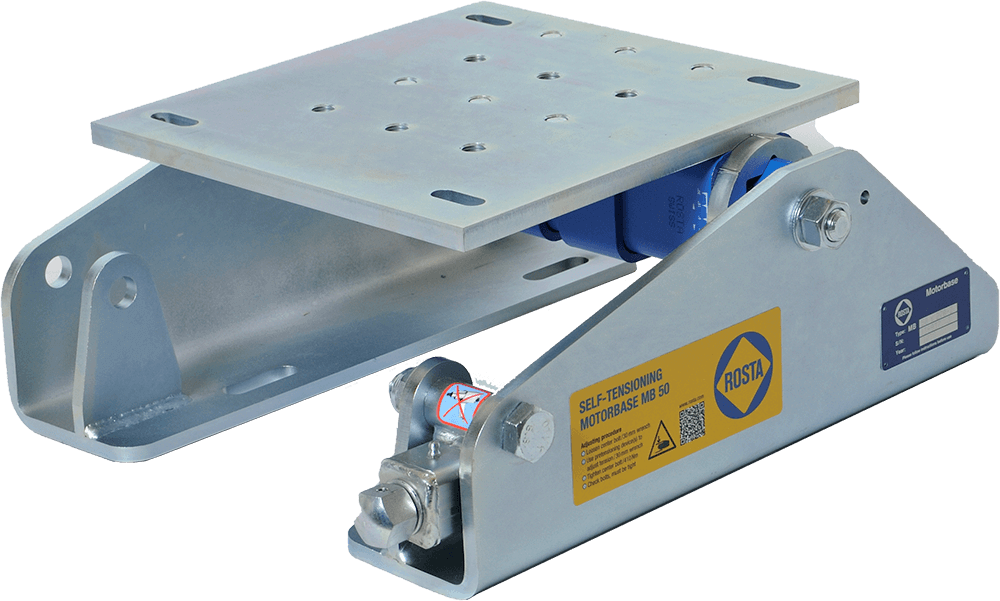

MB 50型ROSTA电机弹性张紧底座适用于电机功率7.5KW-45KW(电机规格型号从160M至225M),该型号应用最为广泛。

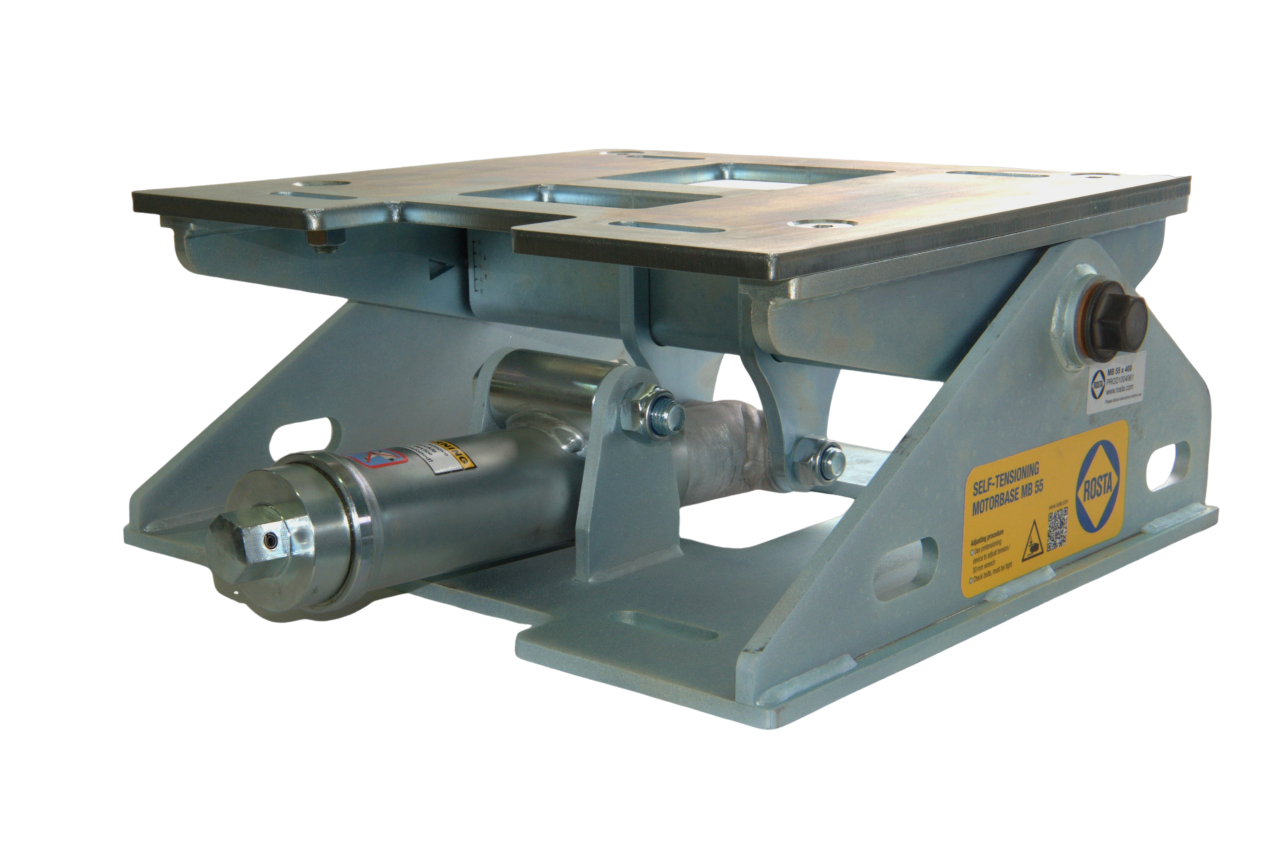

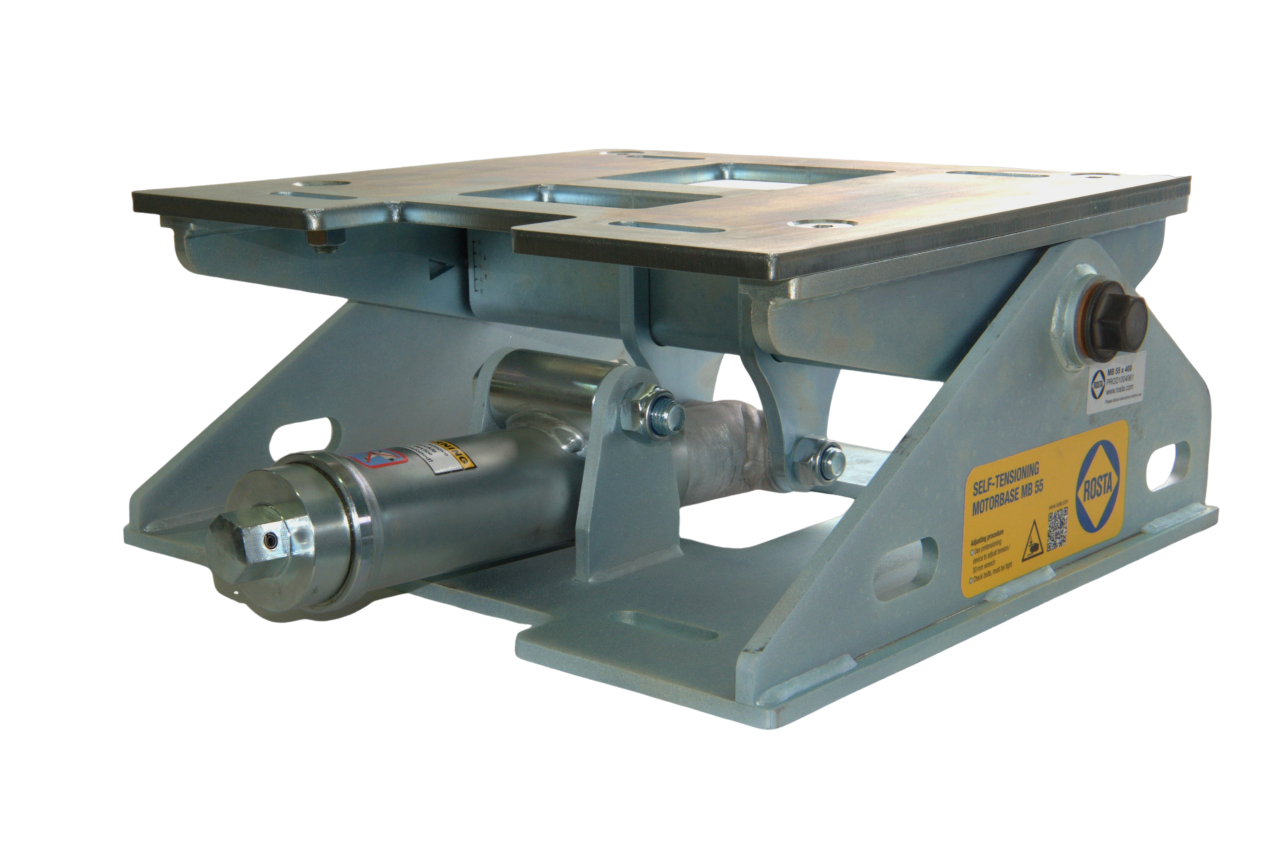

ROSTA新型电机弹性张紧底座 MB 55系列,适用于多种规格电机,包括中央预张紧装置,上下两个板都支持安装电机,具有可互换的电机安装板,可用于中心或偏心位置,并提供三种尺寸。

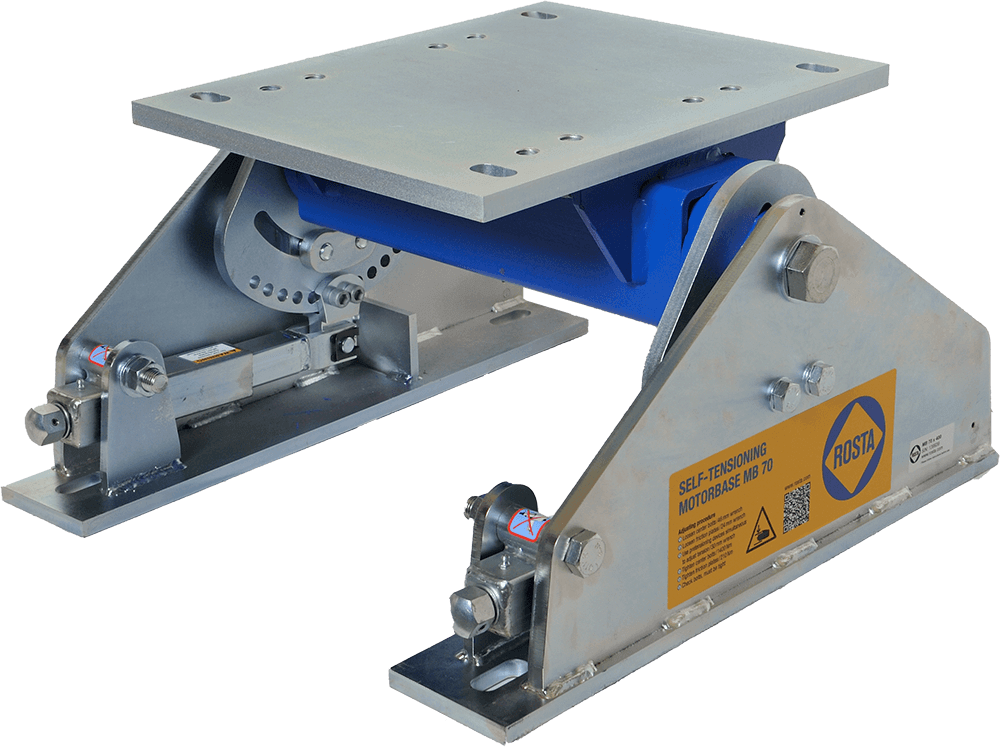

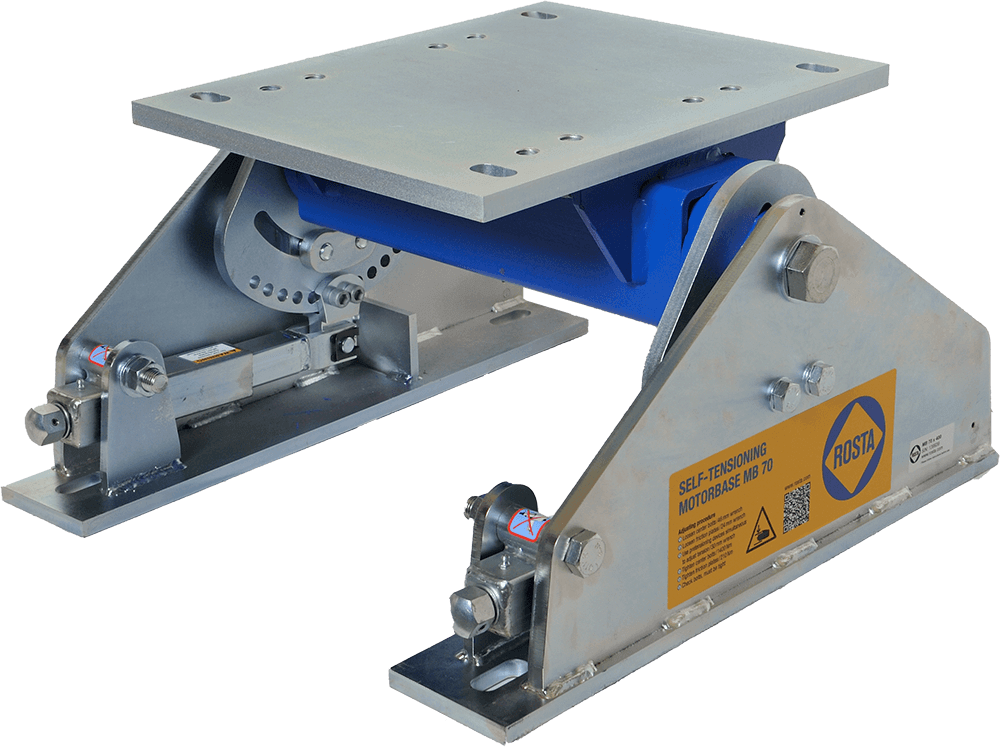

MB 70型ROSTA电机弹性张紧底座适用于电机功率37KW-200KW(电机规格型号从250M至315L),该型号适合重型皮带传动。

MB 75型ROSTA电机弹性张紧底座的特点是中心预张紧调节装置,便于操作。(类似于MB100型)

SE-B型ROSTA弹性张紧装置适用于非常长的皮带或链条驱动场合。

SE-G型ROSTA弹性张紧装置有黄色标记,是表面镀锌的钢制件,尤其适合户外环境。

SE-I型ROSTA弹性张紧装置所有零部件采用不锈钢制作。

SE-W型ROSTA弹性张紧装置有红色标记,配有耐热弹性橡胶体。

世界各地的许多公司都给予我们的产品较高评价并将其推荐给其他公司。请自行阅读,了解客户对我们的产品体验有什么看法。

ROSTA元件是一款弹性体动力扭簧,是我们专业机器部件系列的核心,旨在提供多种实用功能。ROSTA组件为广泛的工业应用提供可靠的性能。

"精选的ROSTA元件可通过更换橡胶线、内部安装件或外壳进行翻新。这不仅提高了效率,而且环保。

联系销售人员了解更多关于我们翻新方案的信息。"

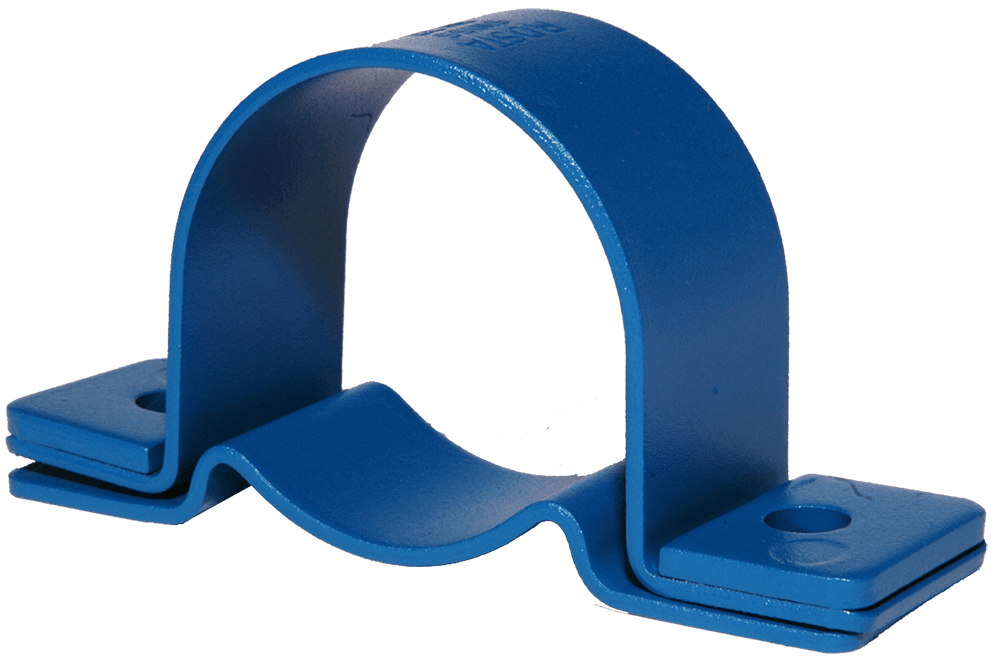

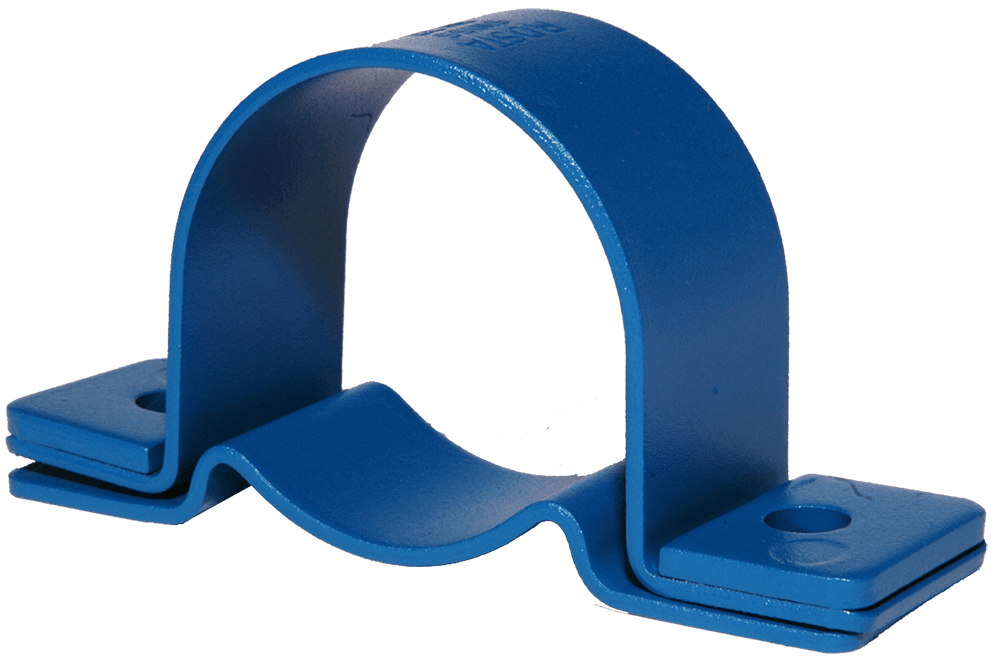

ROSTA组件应通过标准夹具和支架连接在机器零件/结构上。

ROSTA组件应通过标准夹具和支架连接在机器零件/结构上。

优质的滚轮由耐磨工业塑料制成,可在骑乘器两侧使用。

"链轮在自润滑滚珠轴承2Z.C3上运行。"

ROSTA组件应通过标准夹具和支架连接在机器零件/结构上。

张紧滚筒由工业塑料材料制成,带有两个自润滑滚珠轴承2Z.C3,设计用于轻型驱动装置。

滚筒由优质的工业塑料材料制成,带有两个自润滑滚珠轴承2Z.C3。

ROSTA链轮组为链传动应用提供完整的张紧元件。

优质的滚轮由耐磨工业塑料制成,可在骑乘器两侧使用。

适用于各类筛分机和振动输送机的弹性悬挂。ROSTA提供广泛的振荡支座。包括标准支座和重型支座。也可采用不锈钢制作。

和我们联系。查找您所在国家或离您最近的ROSTA公司或ROSTA分销合作伙伴,并告知我们要如何为您提供支持,帮助您在市场上取得成功