ROSTA Product Overview

ROSTA has a wide selection of products and services that will help you improve application performance increase your productivity.

Search by category

Search by description

Types

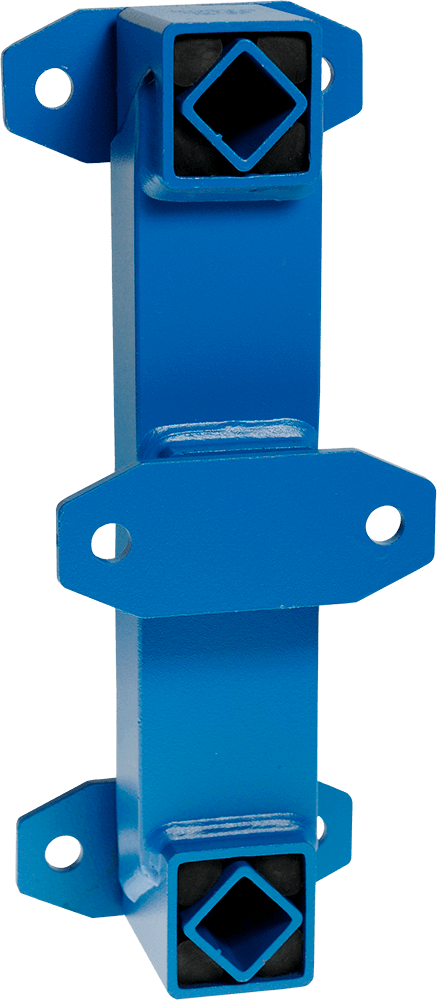

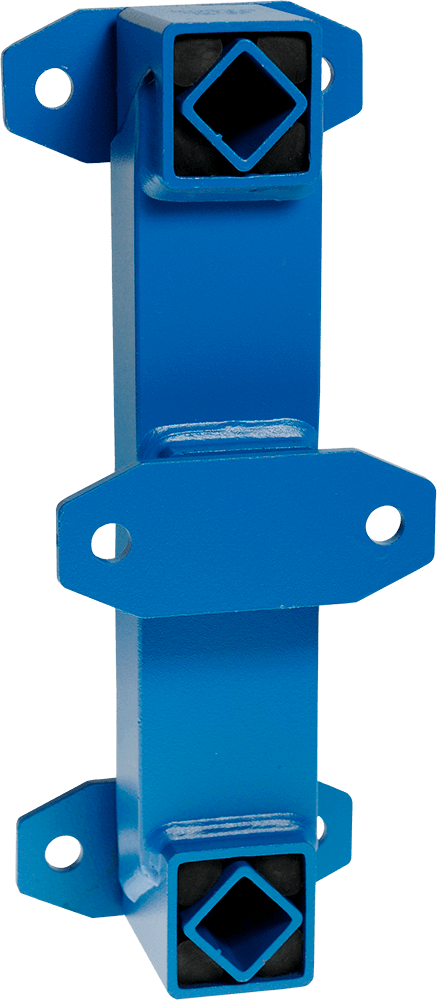

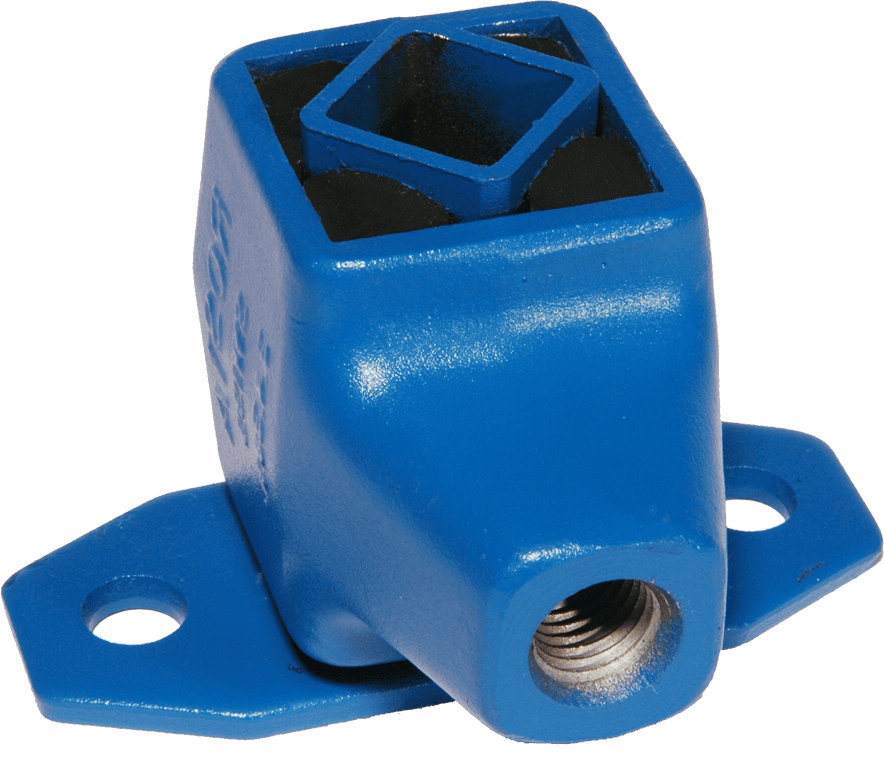

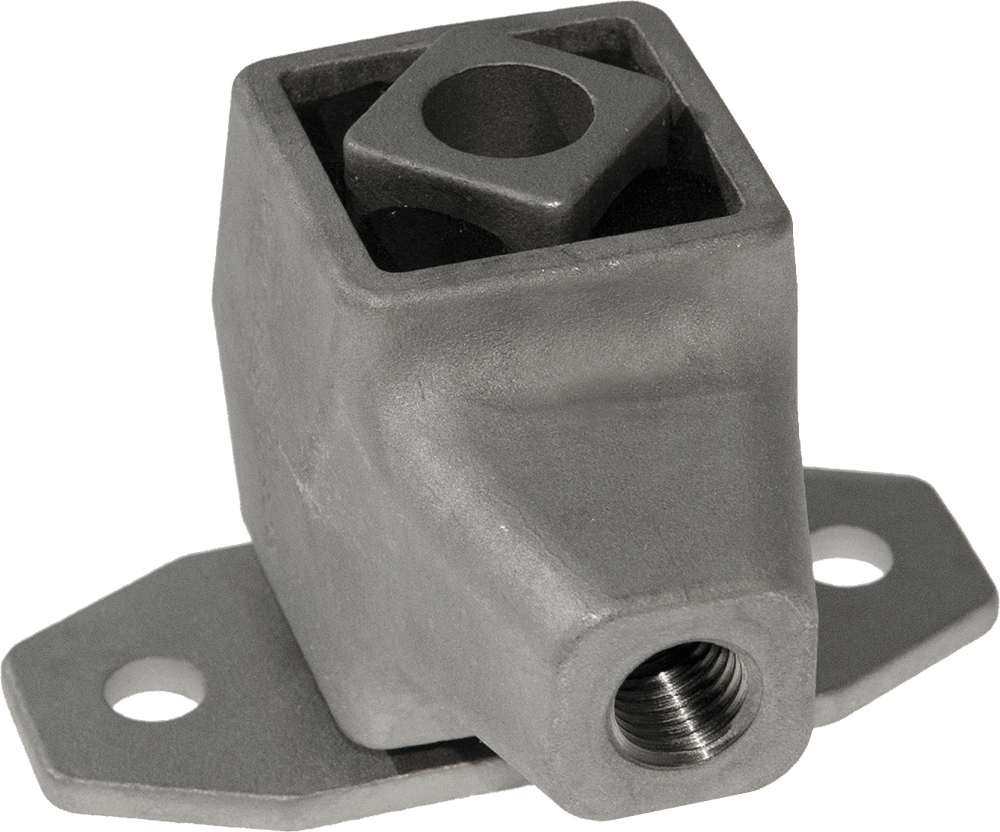

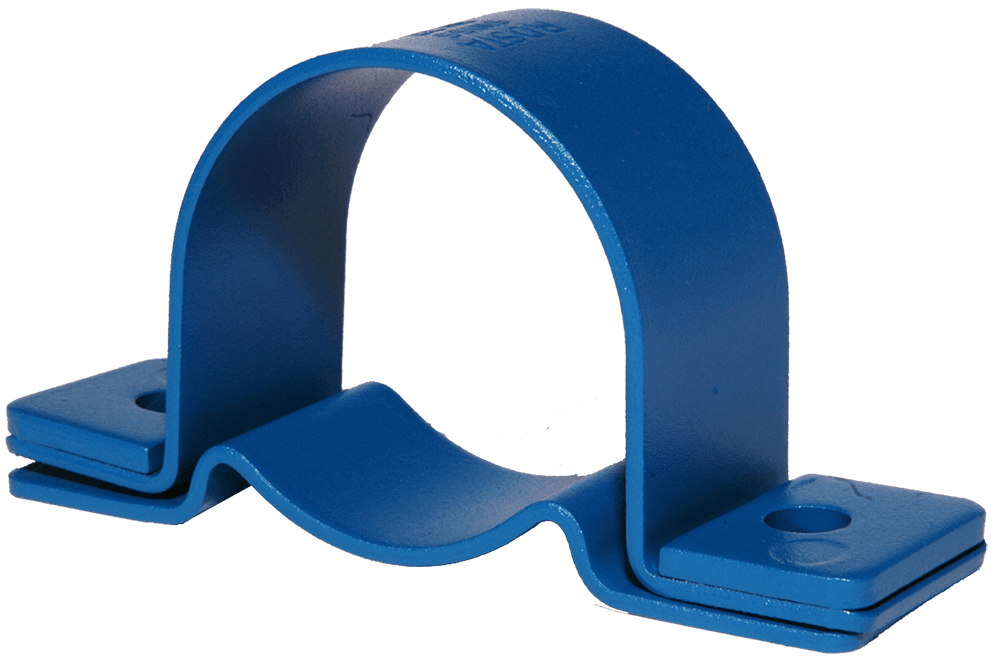

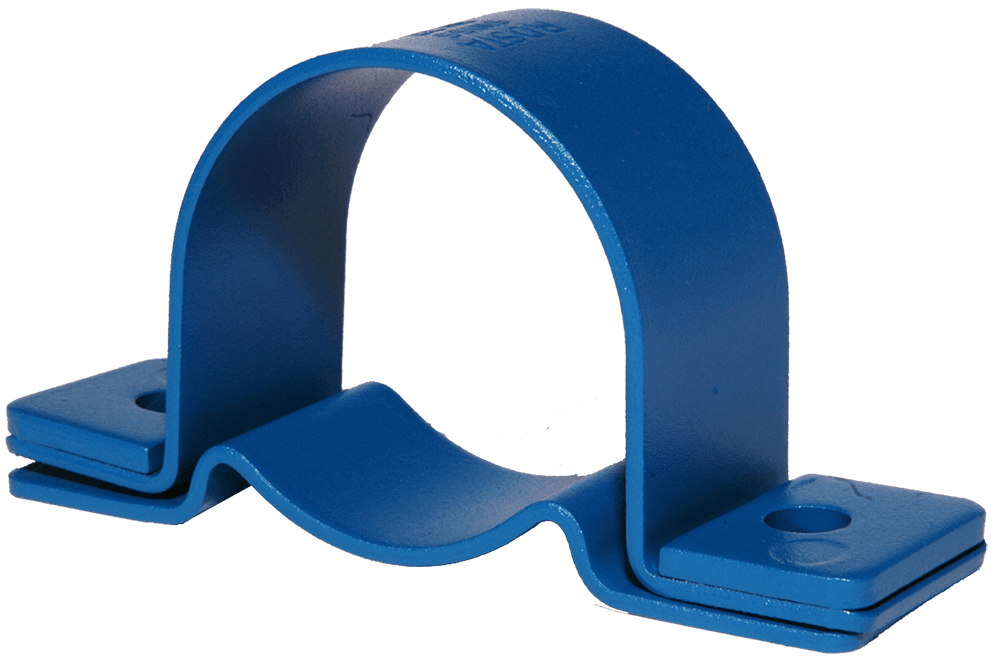

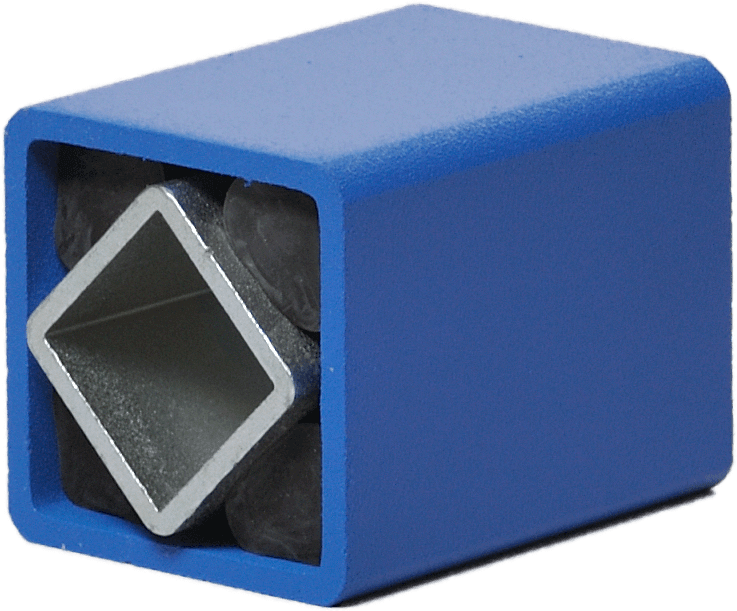

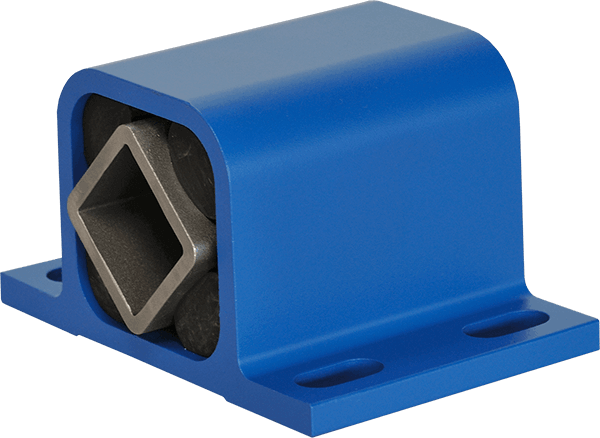

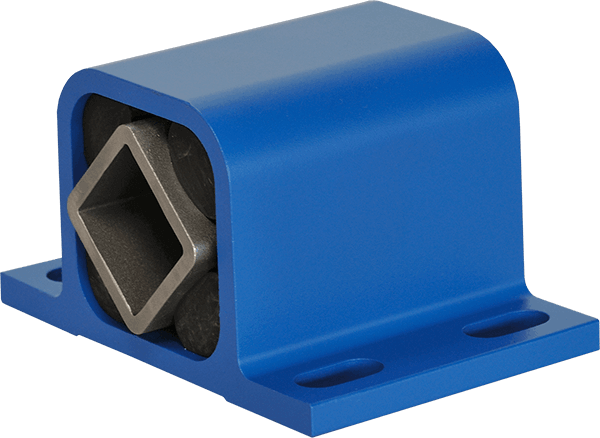

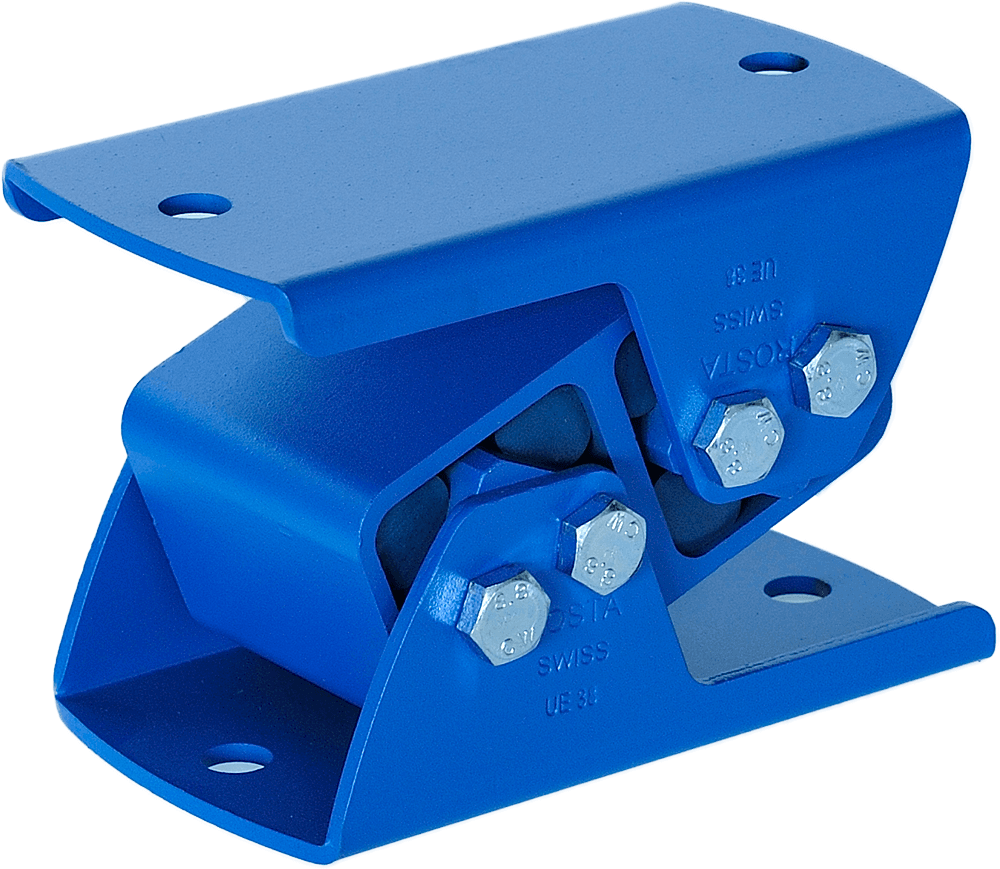

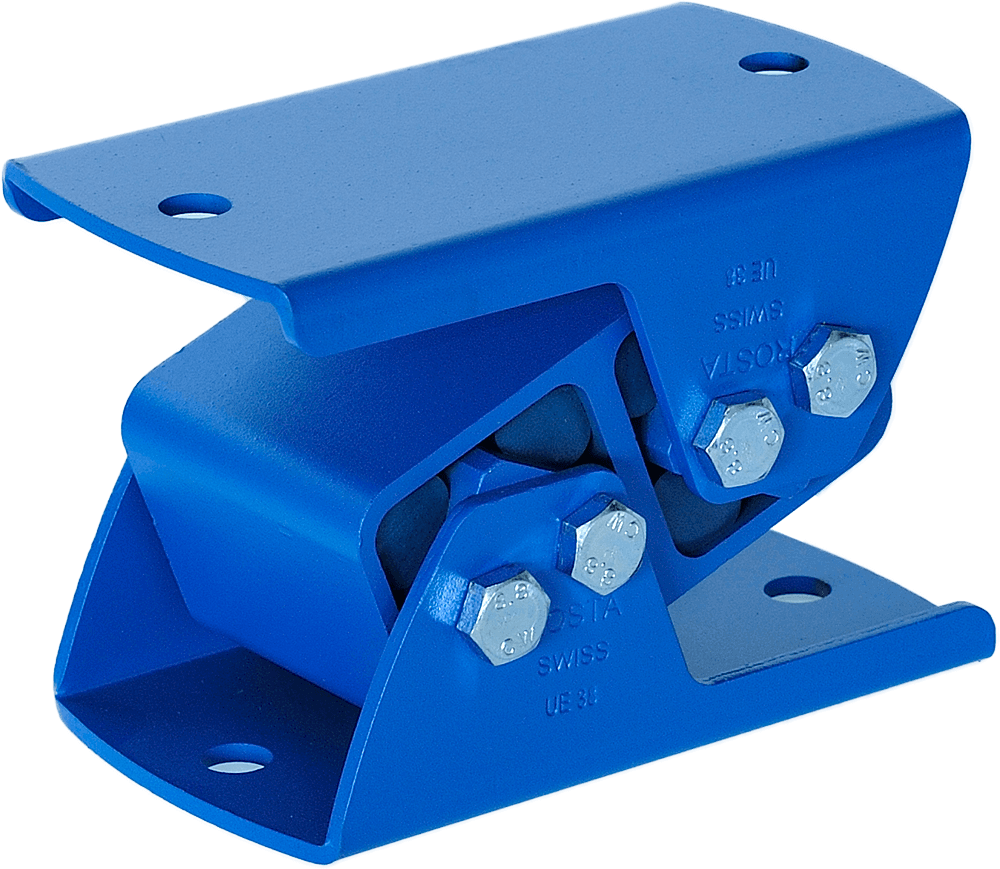

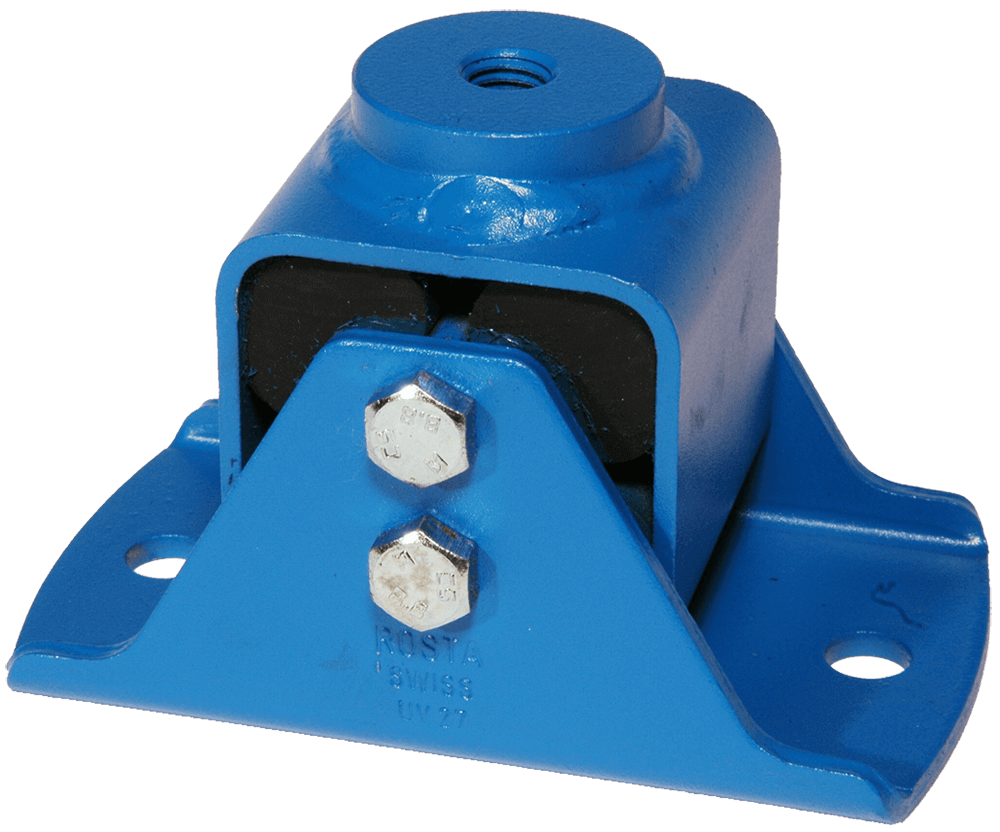

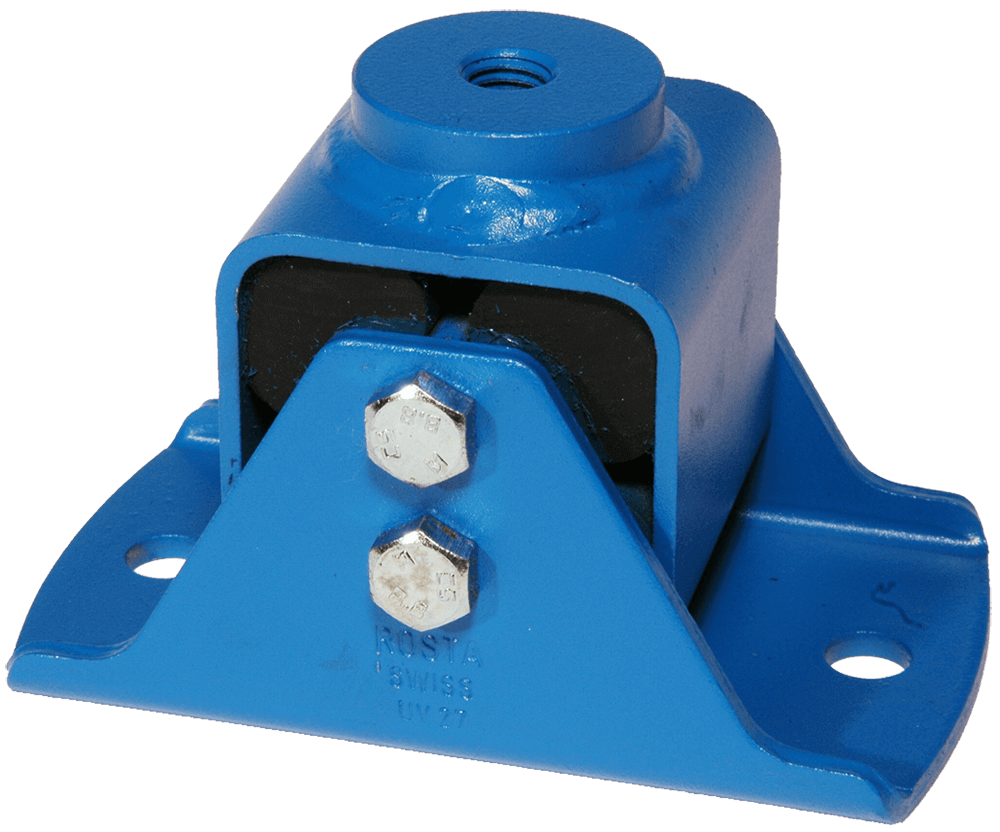

Type AB

ROSTA AB oscillating mountings set THE STANDARD in high performance suspension systems with dependable durability for freely oscillating vibrating equipment. Suitable for a wide variety of machine designs and specification. All AB oscillating mountings are also available in stainless steel (AISI 304) and interchangeable with the blue AB oscillating mountings.

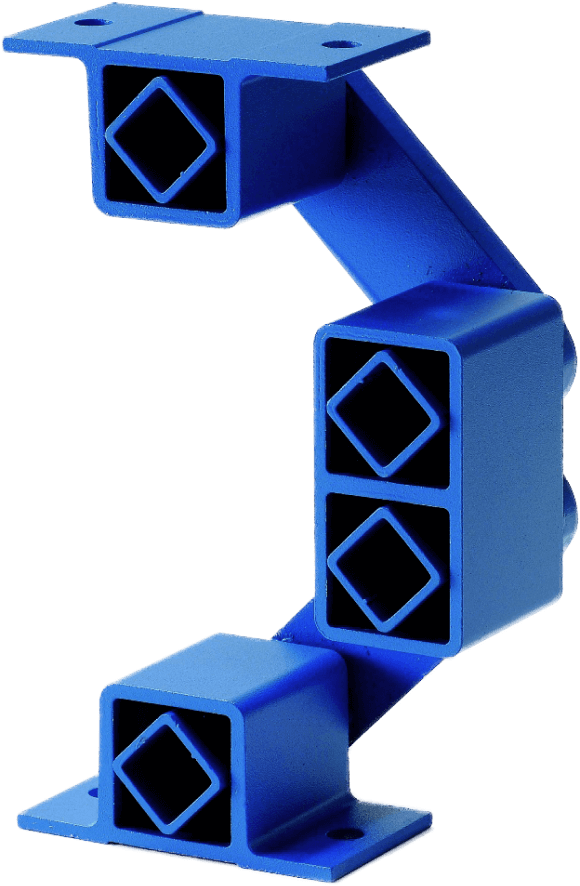

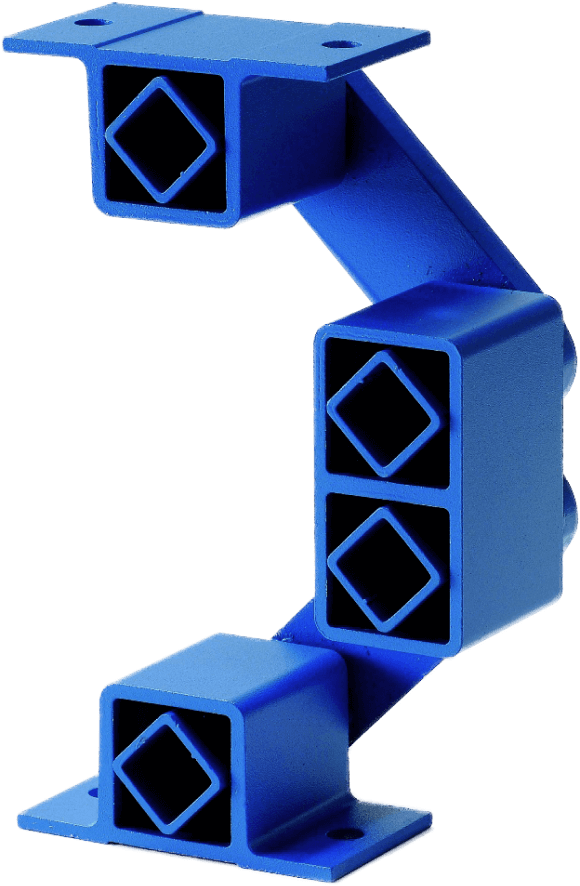

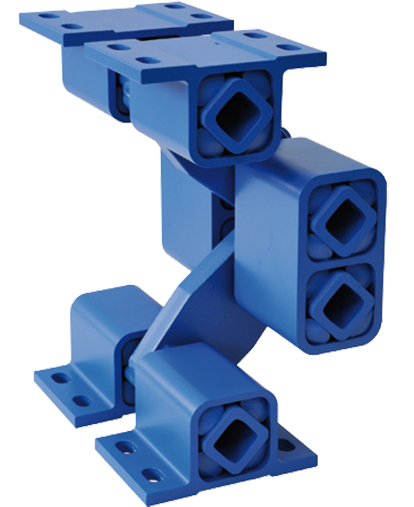

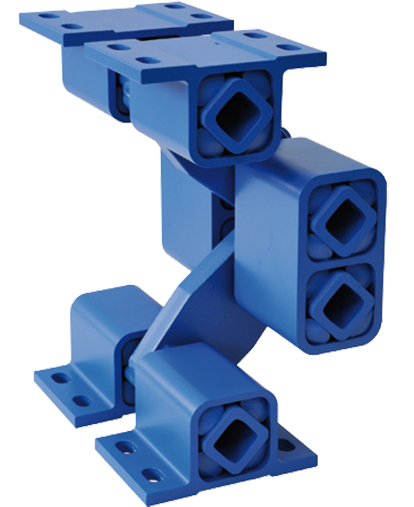

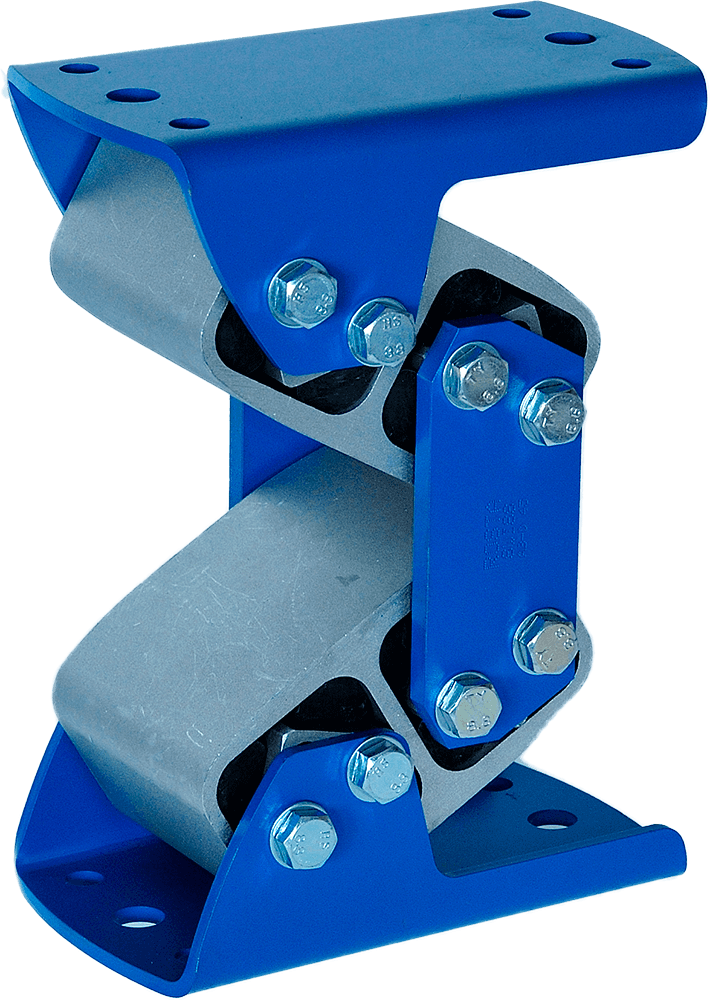

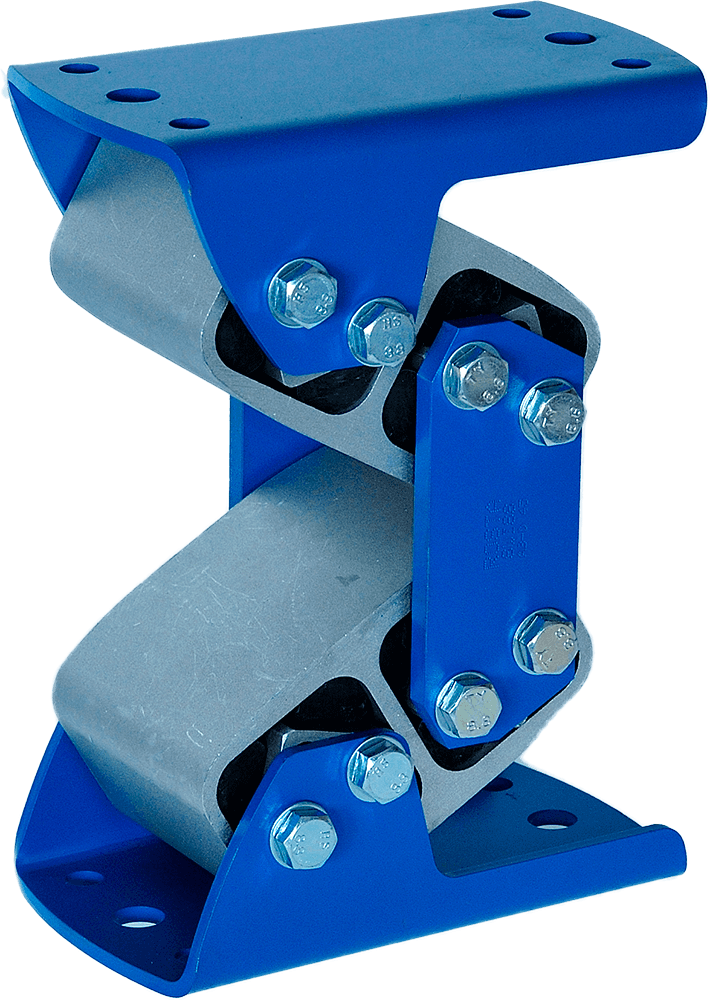

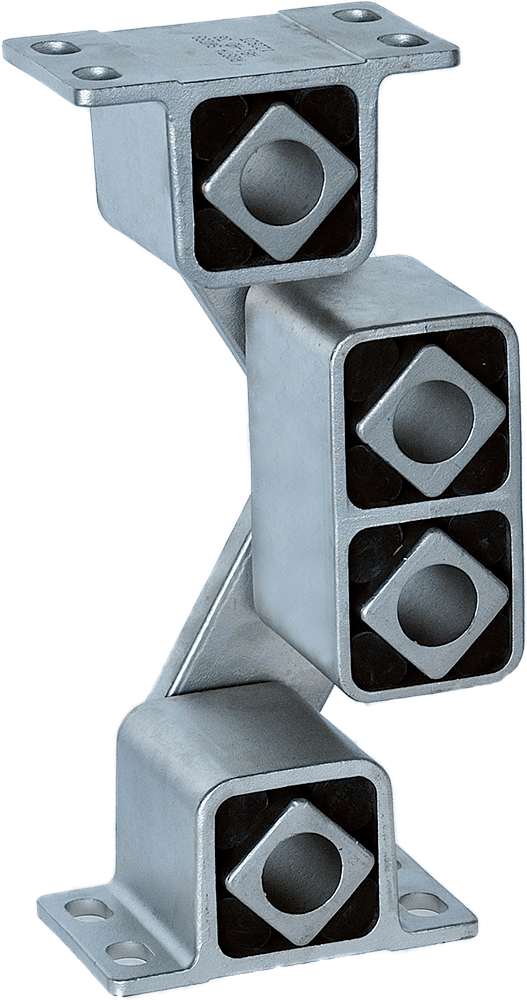

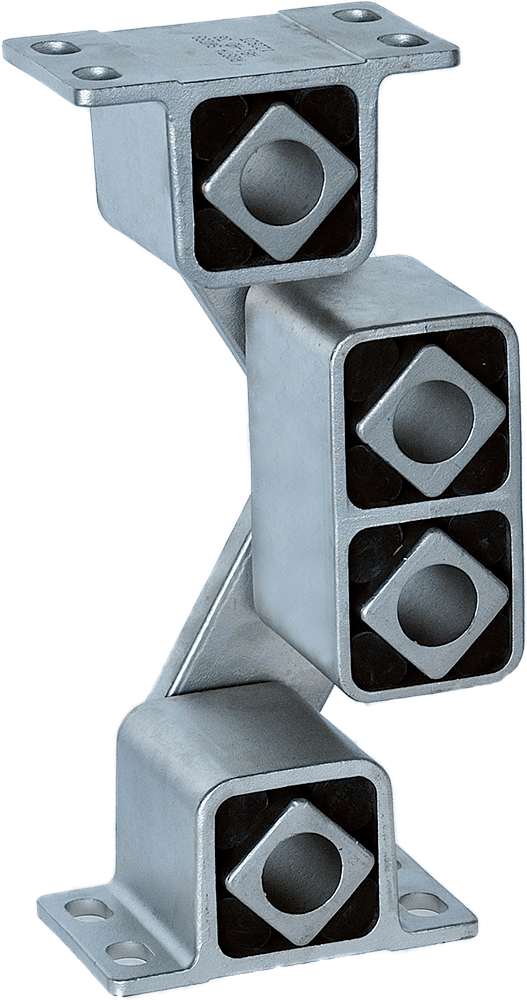

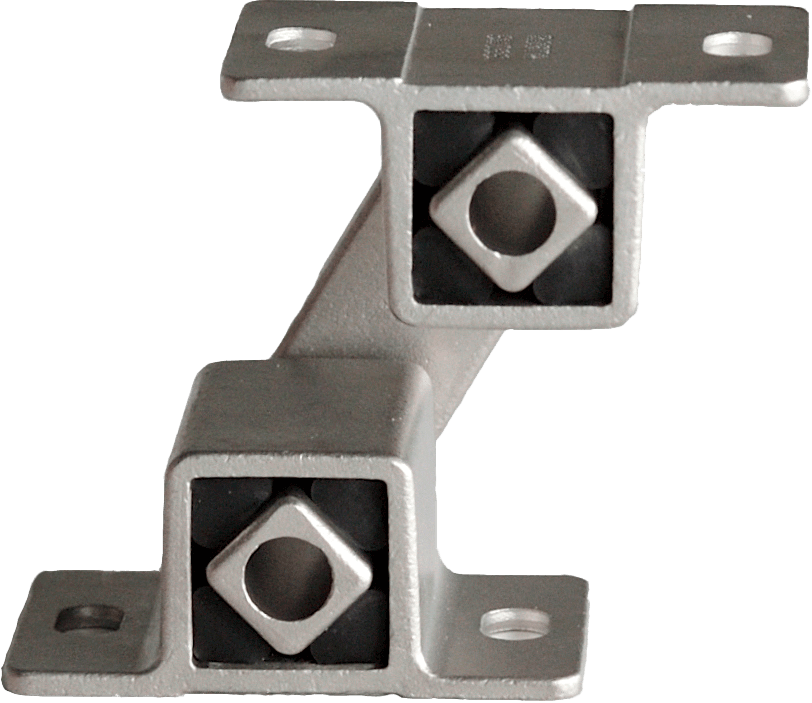

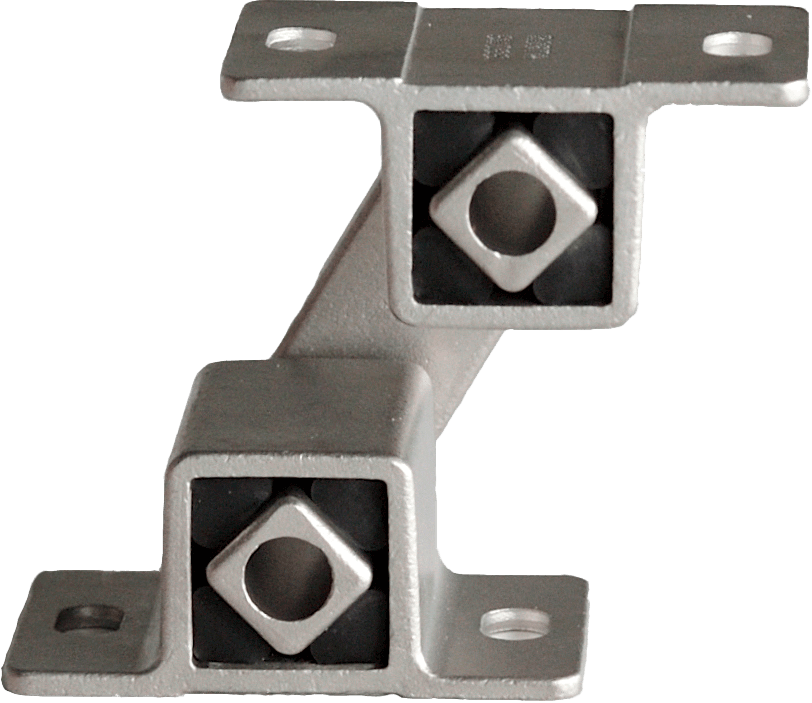

Type AB TWIN

ROSTA AB50 TWIN and 50-2 TWIN offer very high loading capacities as a result of the special twin construction.

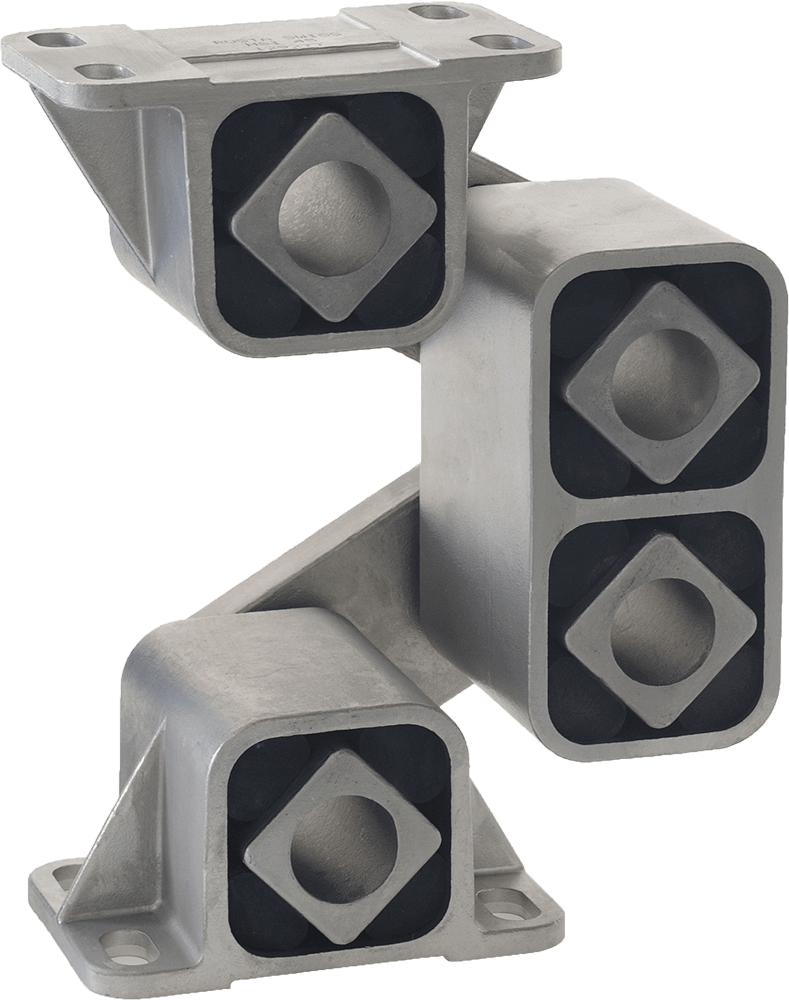

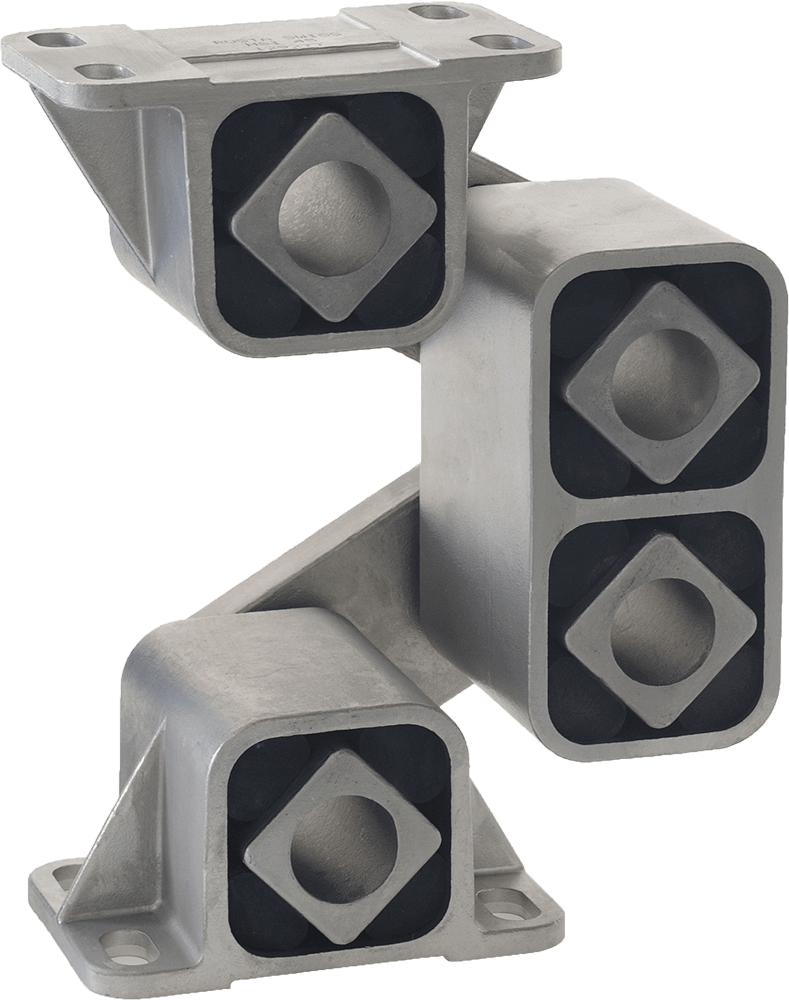

Type AB-D

The AB-D offers a much higher loading capacity than the AB for the same compact design.

Type AB-HD

The oscillating mounting type AB-HD is the "Heavy Duty" version in the AB mount family of the ROSTA screen suspensions.

Type AB-LF

The ROSTA AB-LF series features oscillating mountings with a patented design, achieving a low inherent frequency of 2 Hz, suitable for applications requiring efficient vibration isolation.

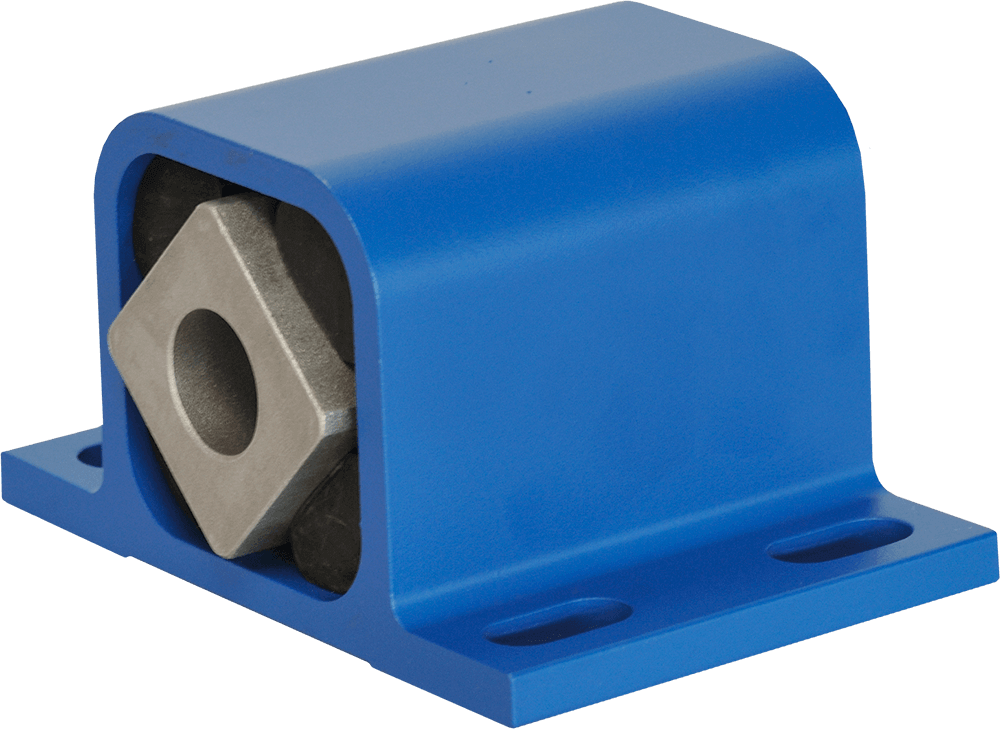

Type ABI

ROSTA oscillating mountings type AB are maintenance-free elastic rockers for the support or suspension of freely oscillating vibrating equipment with a wide variety of designs and drive systems.

Type ABI-HD

The oscillating mounting type ABI-HD is the "Heavy Duty" version in the AB mount family of the ROSTA screen suspensions.

Type AD-C

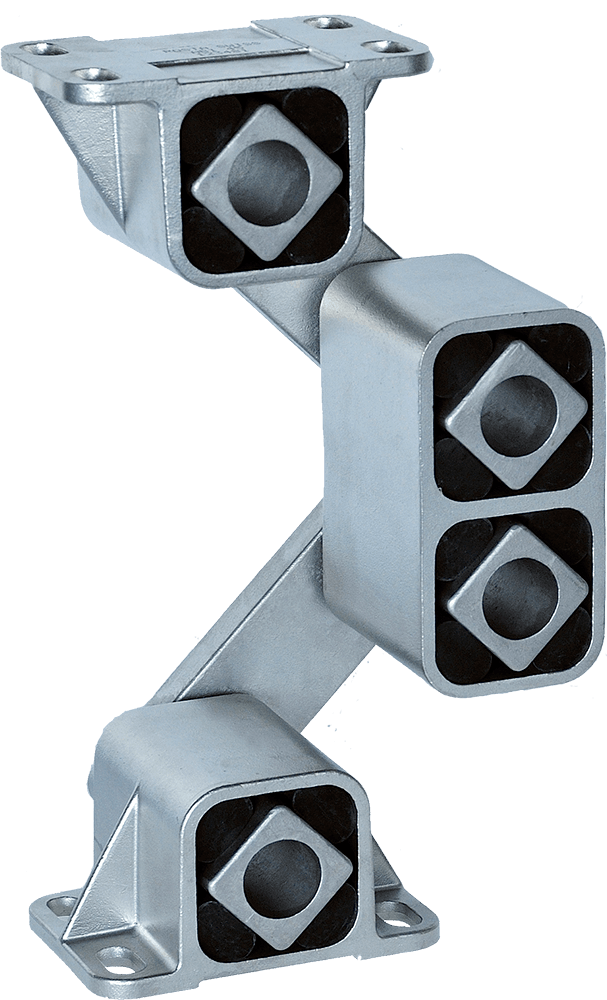

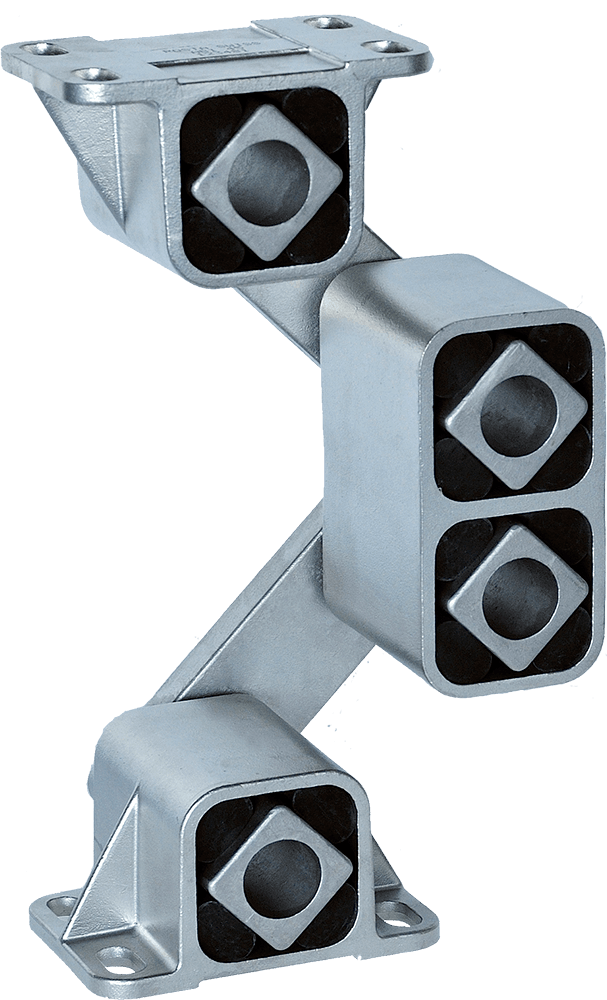

The ROSTA double suspension units type AD-P/AD-C are used for suspending and supporting two-mass shaker systems.

Type AD-P

The ROSTA double suspension units type AD-P/AD-C are used for suspending and supporting two-mass shaker systems.

Type AD-PV

The ROSTA double suspension units type AD-PV/AD-C are used for suspending and supporting two-mass shaker systems.

Type AK

The ROSTA universal joints type AK are maintenance-free elastic joints which can be moved in any direction.

Type AR

The ROSTA oscillating mountings type AR are maintenance-free elastic joints used for the same purposes as our other oscillating mounting types AU, AS or AD.

Type AS-C

The ROSTA rocker suspension units type AS-P and AS-C are maintenance-free elastic guide arms used for the same purposes as the oscillating mounting type AU.

Type AS-P

The ROSTA rocker suspension units type AS-P and AS-C are maintenance-free elastic guide arms used for the same purposes as the oscillating mounting type AU.

Type AS-PV

The ROSTA rocker suspension units type AS-PV and AS-C are maintenance-free elastic guide arms used for the same purposes as the oscillating mounting type AU.

Type AU

ROSTA oscillating mountings type AU are maintenance-free elastic joints for suspending or supporting conveying.

Type AUI

ROSTA oscillating mountings type AUI are maintenance-free elastic joints for suspending or supporting conveying.

Type AV

The ROSTA oscillating mountings type AV are maintenance-free elastic joints designed for guiding circular motions of hanging screens such as gyratory sifters and screens in flour mills, chemical processing plants and paper mills.

Type AWI

ROSTA anti-vibration mounts type AWI are intended for the absorption of medium and low frequency vibrations.

Type BK

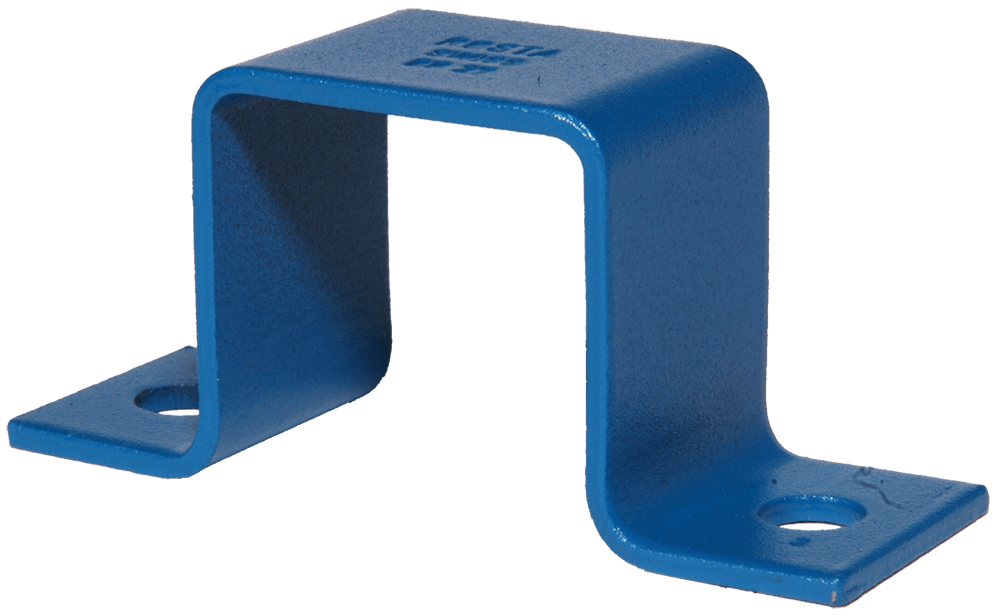

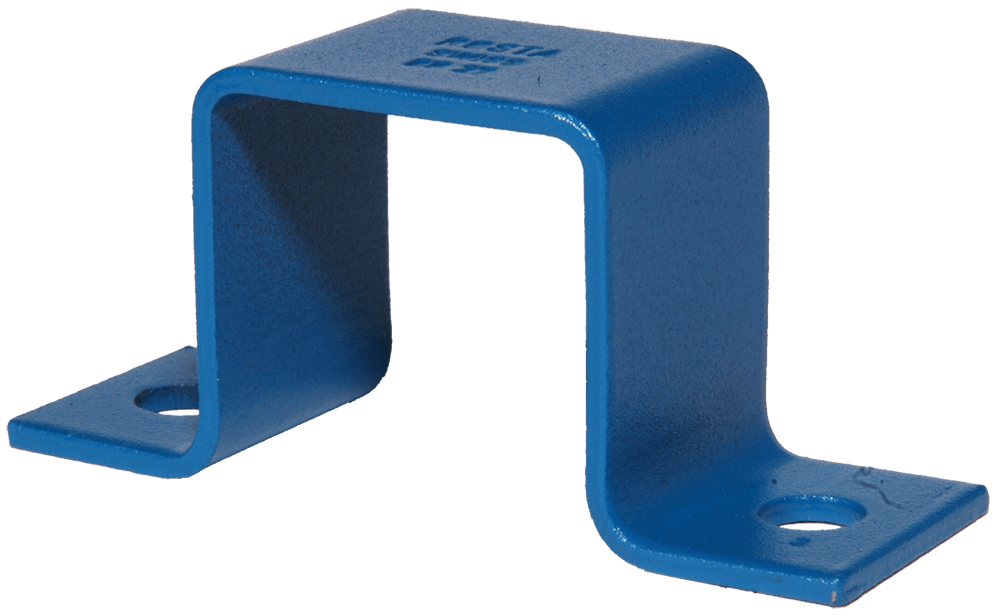

ROSTA modules should be connected on machine parts/structures by means of the standardized clamps and brackets.

Type BR

ROSTA modules should be connected on machine parts/structures by means of the standardized clamps and brackets.

Type Chain Rider P

This high-quality rider is made of friction resistant industrial plastic and allows the use on both rider sides.

Type Chain Rider Type Set-P

The high-quality rider is made of friction resistant industrial plastic and allows the use on both rider sides.

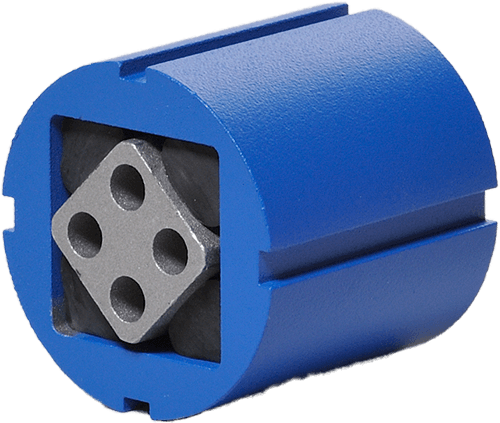

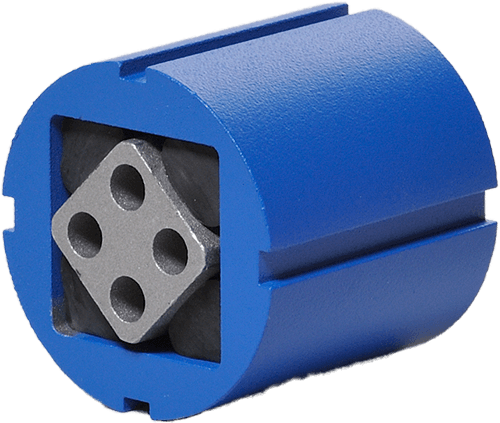

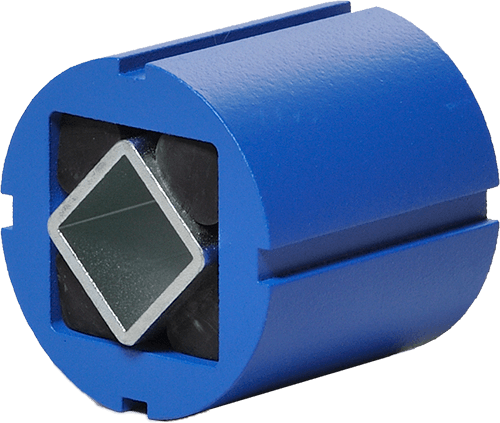

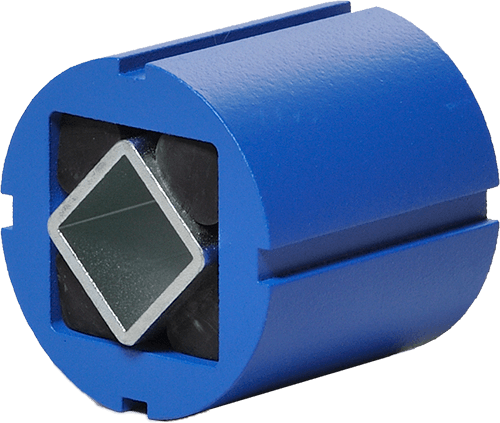

Type DK-A

Round housing and inner square section made of light alloy profiles.

Type DK-S

Round housing and inner square section made of light alloy profiles.

Type DO-A

Housing up to size 45 made out of light alloy profile, size 50 made out of spheroidal graphite cast iron, inner square section made out of light alloy profile with four "throughbores".

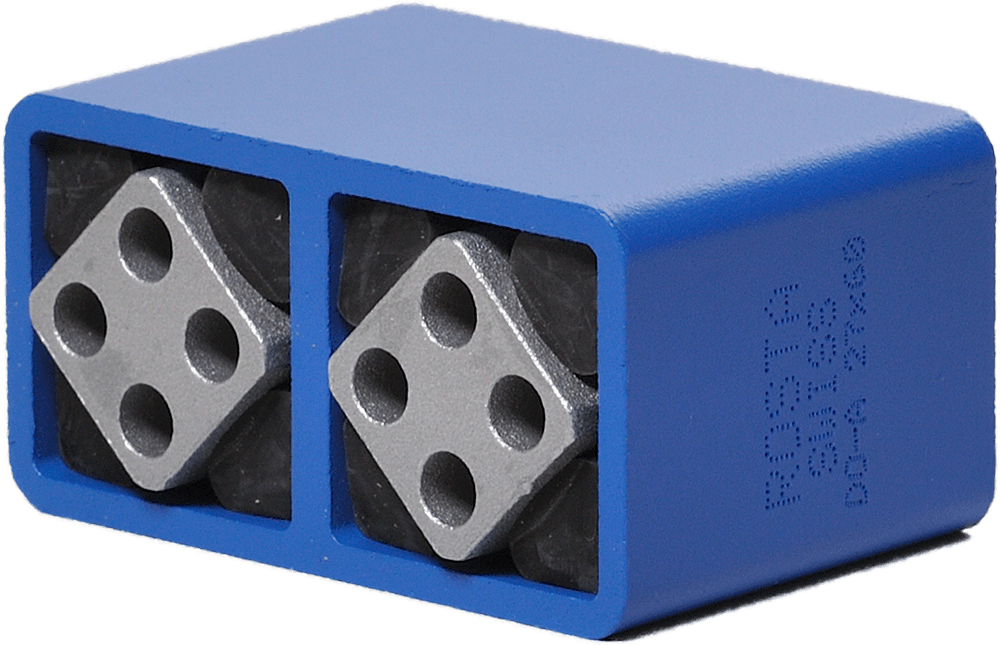

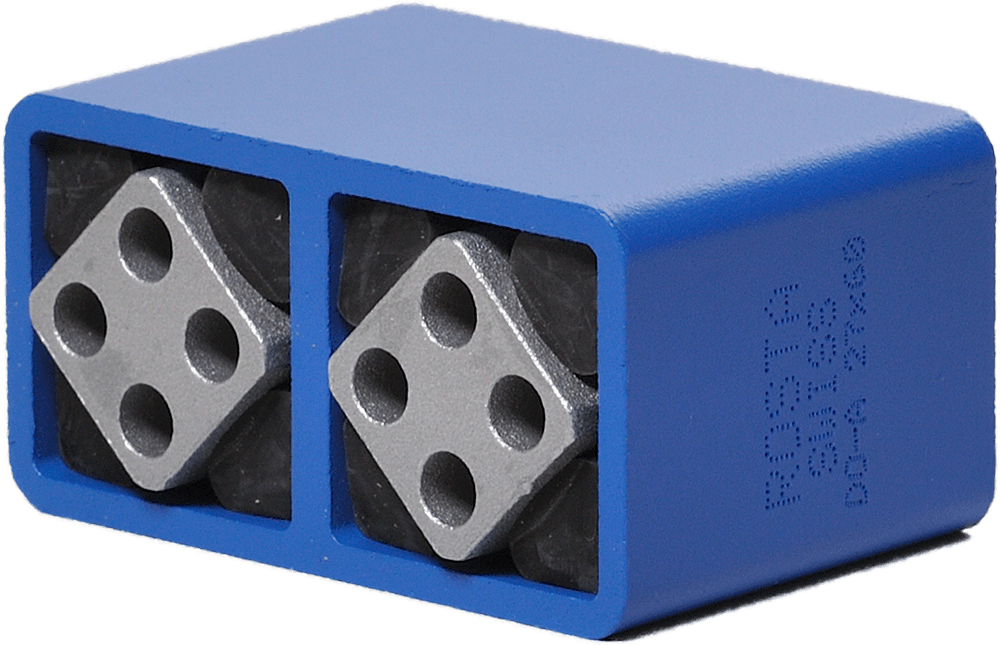

Type DR-A

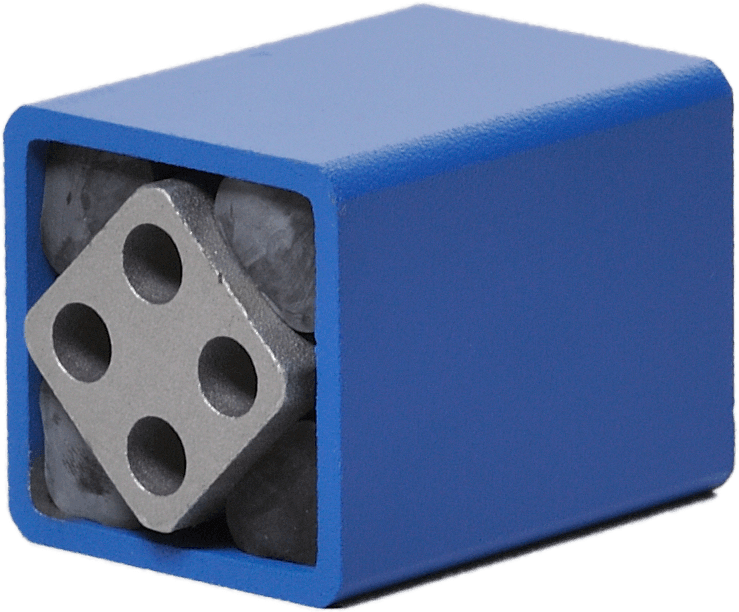

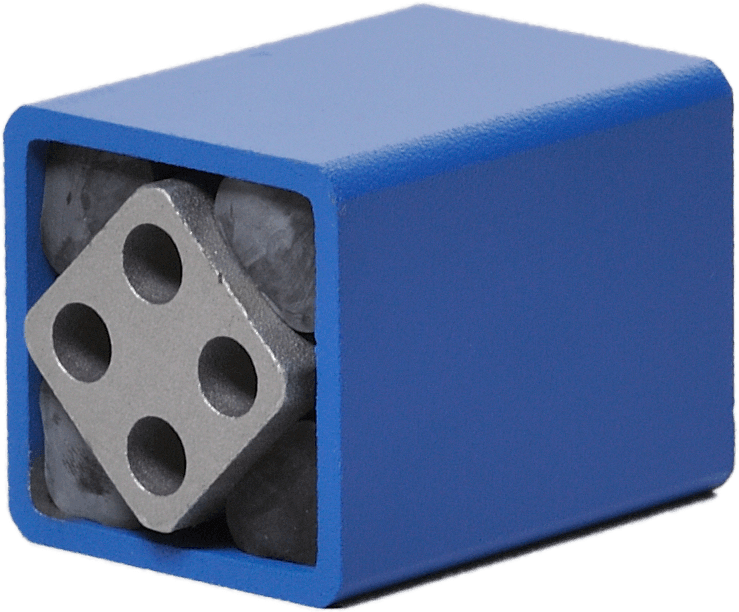

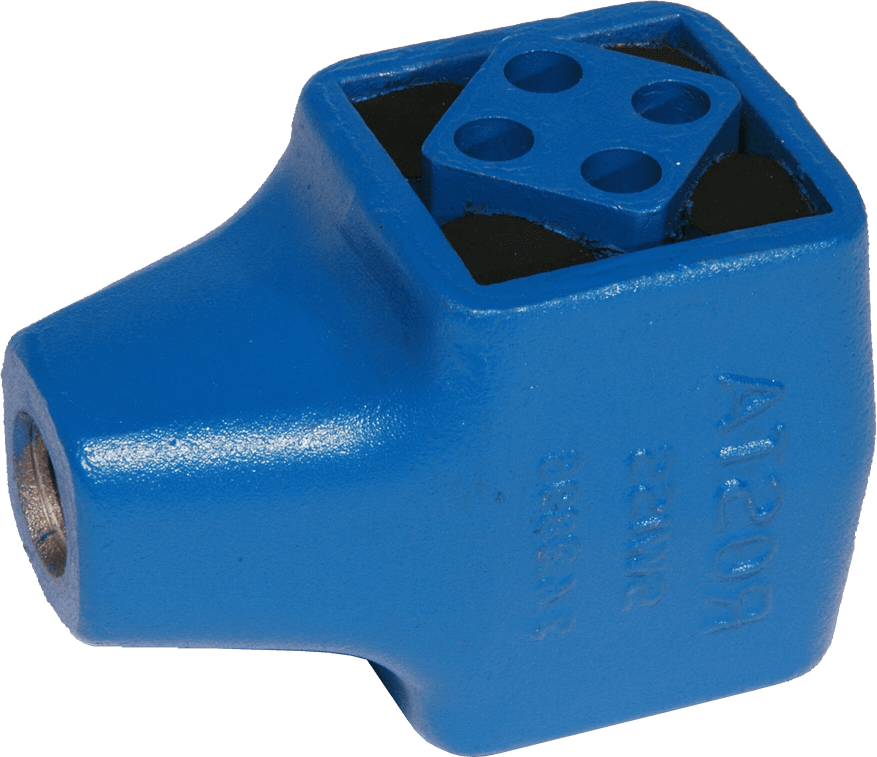

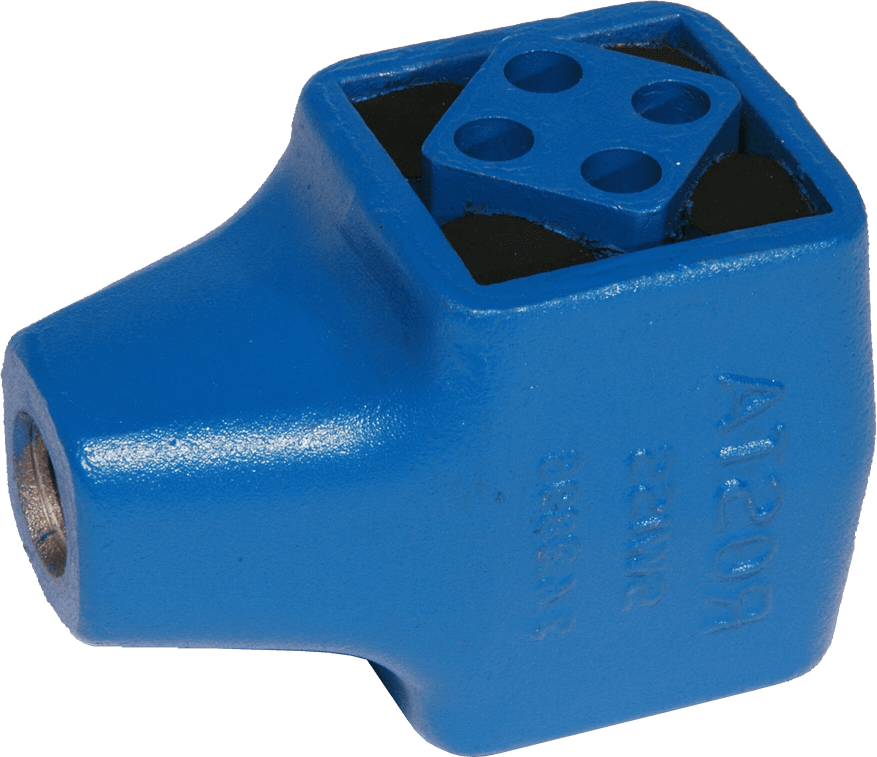

Steel housing with inner square section made of light alloy with four small bores.

Type DR-C

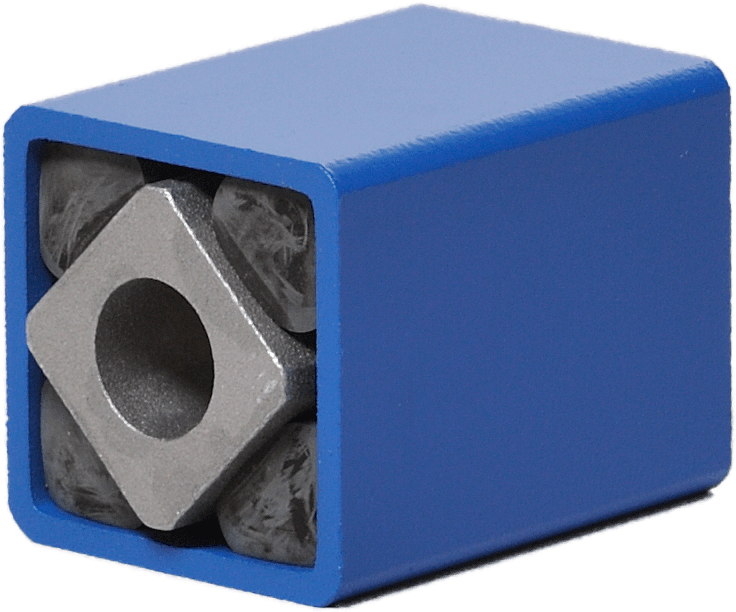

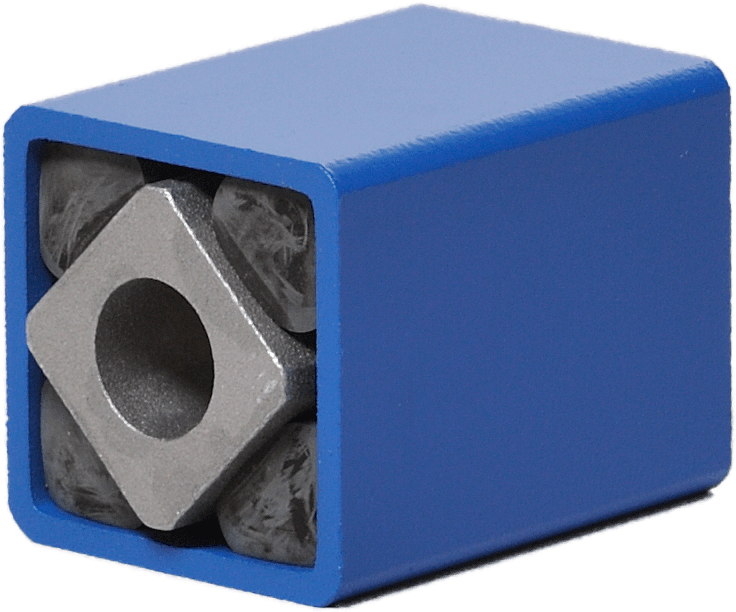

Steel housing with inner square section made of light alloy with one big through bore.

Type DR-S

Housing made out of steel, inner square section made out of steel tube for mounting "plug-in" lever arms on one or both sides.

Type DW-A 15-38

The housings of the element sizes DW-A 15 to 38 are made out of light alloy profile.

Type DW-A 45-50

The housings of the element sizes DW-A 45 and 50 are made out of light alloy profile.

Type DW-A 60-100

The housings of the ele1ment sizes DW-A 45 to 50 are made out of spheroidal cast iron with inner square sections made out of light alloy profile.

Type DW-C 15-38

The housings of the element sizes DW-C 15 to 38 are made out of light alloy profile and are equipped with lateral fixation flanges .

Type DW-C 45-50

The housings of the element sizes DW-C are made out of light alloy profile.

Type DW-S 15-38

The housings of the element sizes DW-S 15 to 38 are made out of light alloy profile.

Type DW-S 45-50

The housings of the element sizes DW-S 45 and 50 are made out of spheroidal cast iron.

Type ESL

ROSTA anti-vibration mounts type ESL are intended for the absorption of medium and low frequency vibrations and are designed to accept compression, tension and shear loading as well as combined loadings.

Type HS

The ROSTA Type HS oscillating mounts have created a good name for themselves.

Type HSI

The ROSTA Type HSI oscillating mounts have created a good name for themselves.

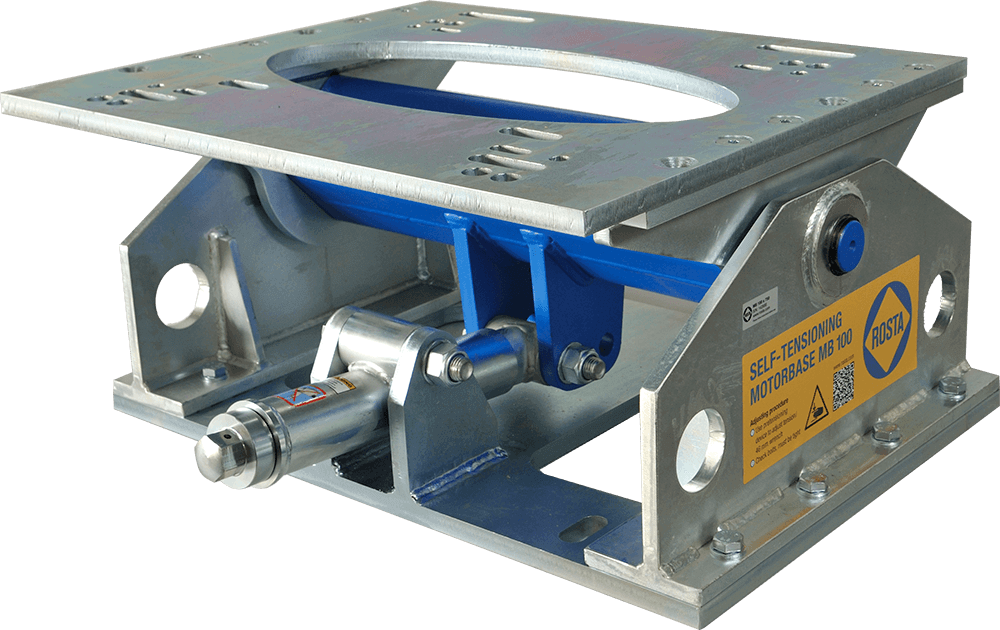

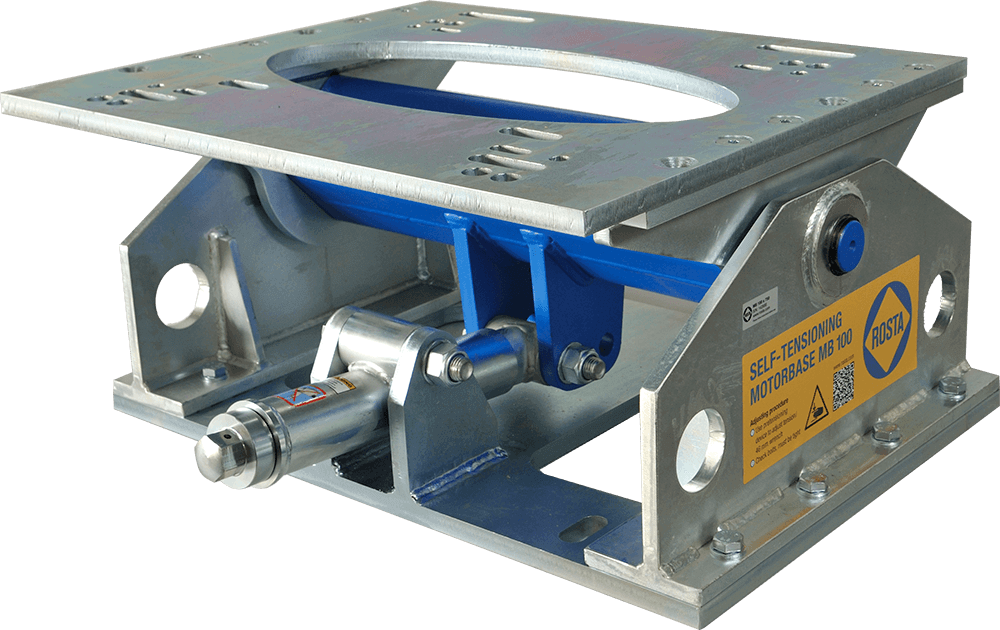

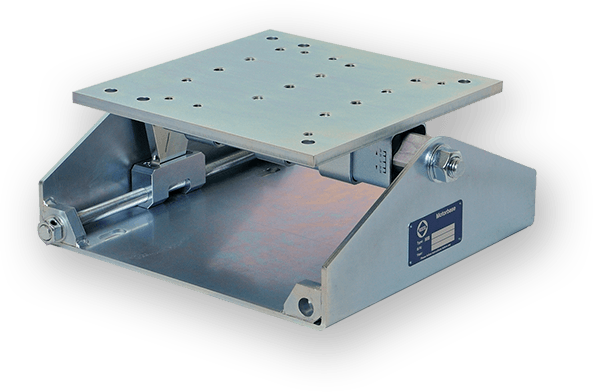

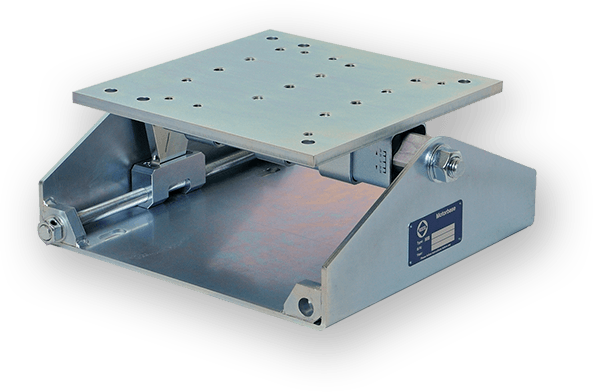

Type MB 100

The self-adjusting universal Motorbase (MB 100) for friction belt drives with drive power in the 90 kW to 250 kW range (motor frame sizes 315 M to 355 L or NEMA frame sizes 449T and 586/7 = 200-350 HP).

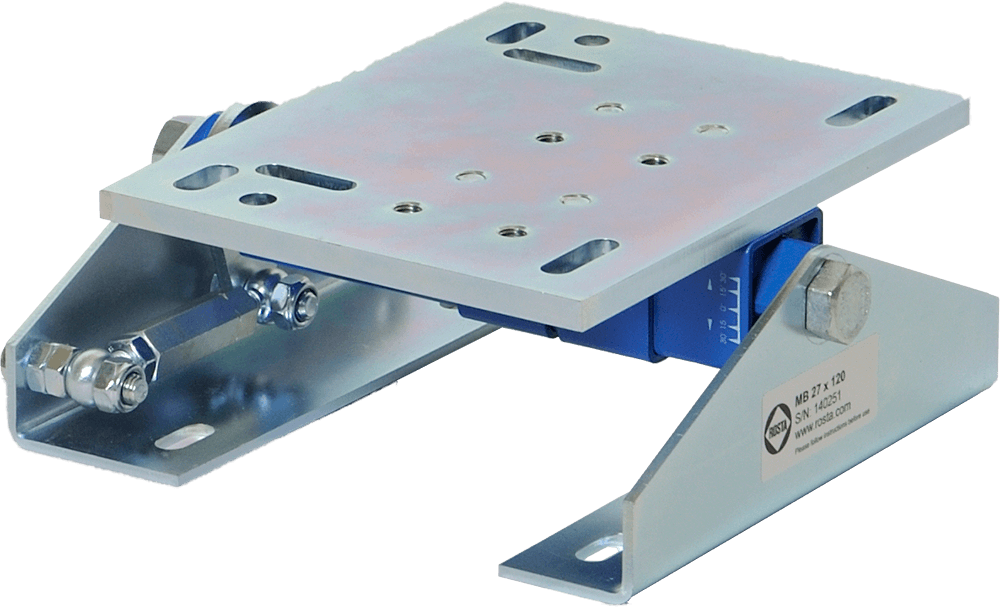

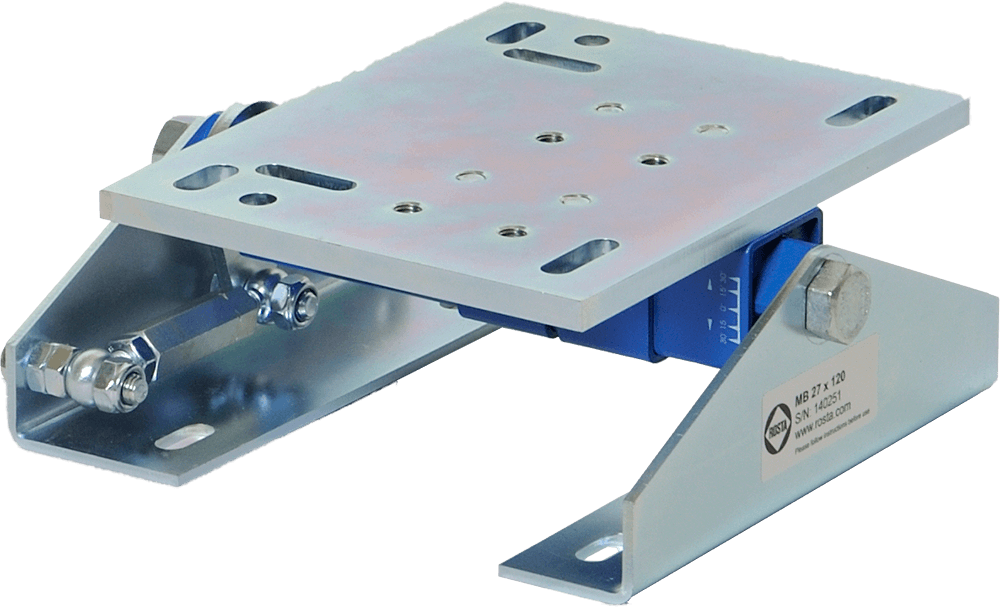

Type MB 27

The ideal standardized motor base for smaller belt drives with electric motors from 0.75 to 4.0 kW (frame size dimensions 90 S/L to 112 M).

Type MB 38

The new ROSTA motor base type MB 38 for motor frame sizes from 132 S to 160 L (3 to 15 kW) is now available on the drive component market - compact, operator friendly, ready for immediate installation and cost-effective.

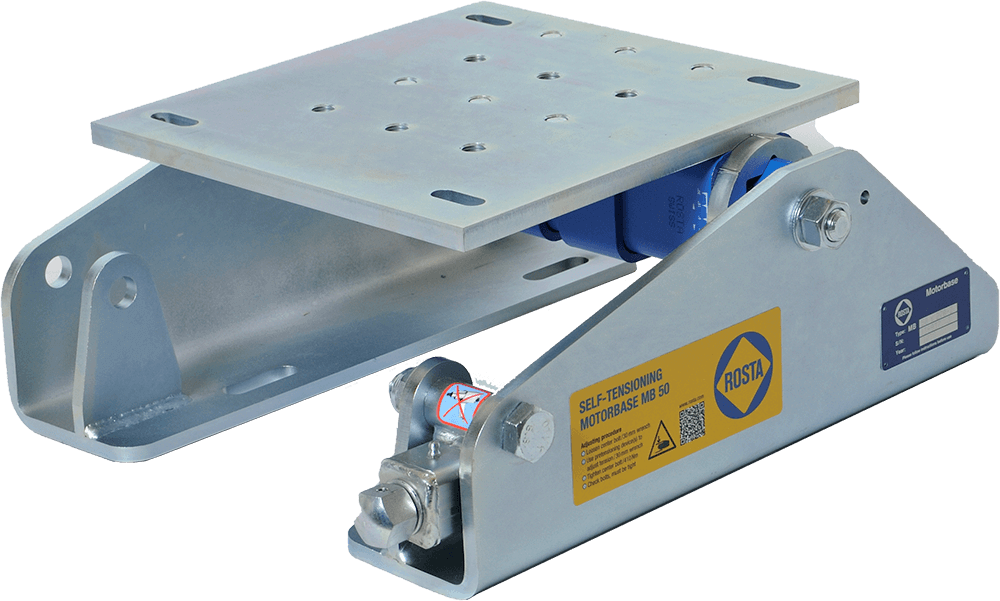

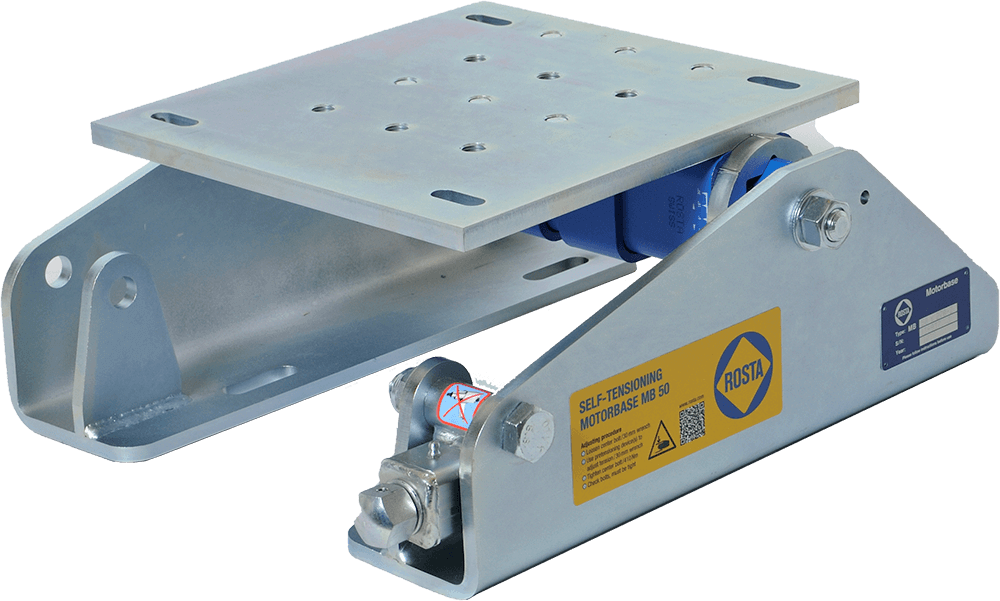

Type MB 50

The type MB 50 is the most universal self-tensioning base for all friction belt drives with 7.5 to 45 kW electric motors (frame size dimensions 160 M S to 225 M).

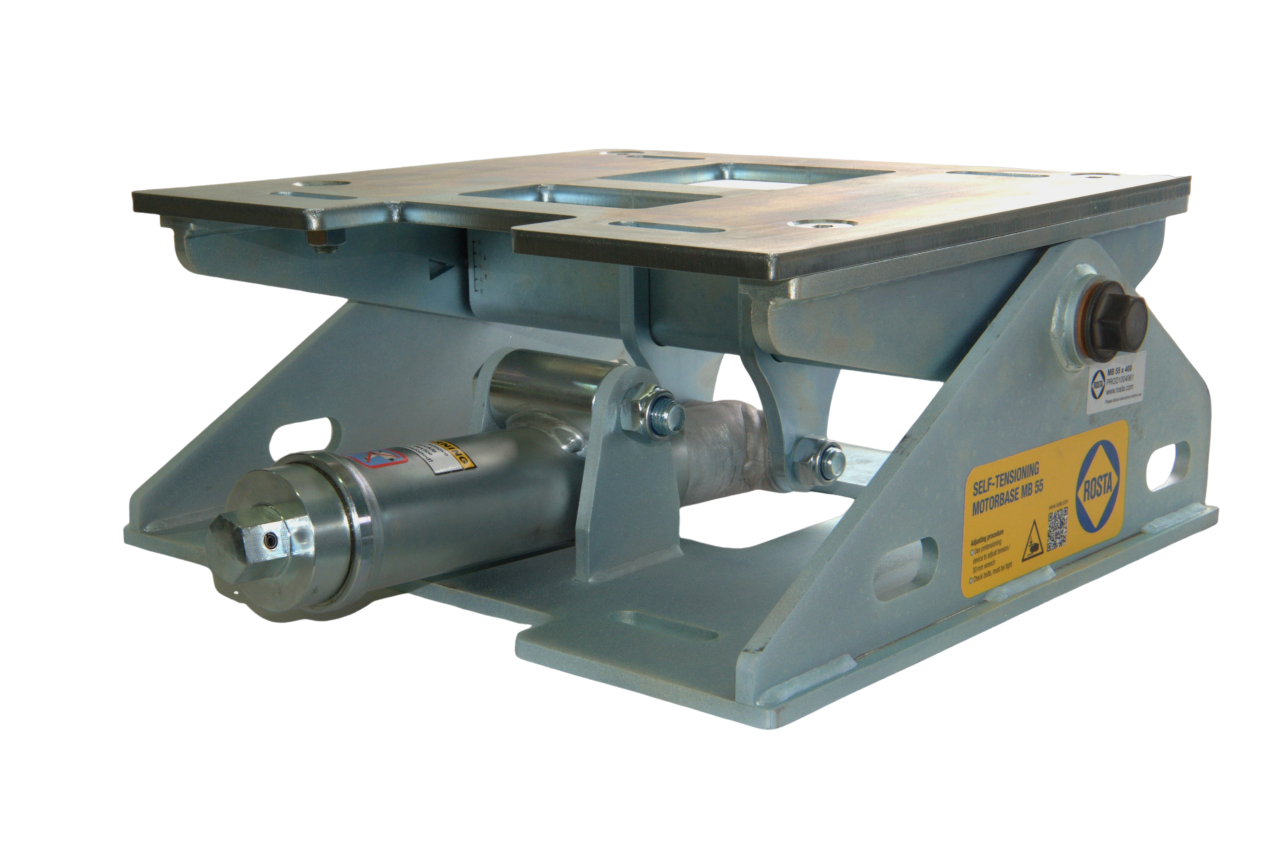

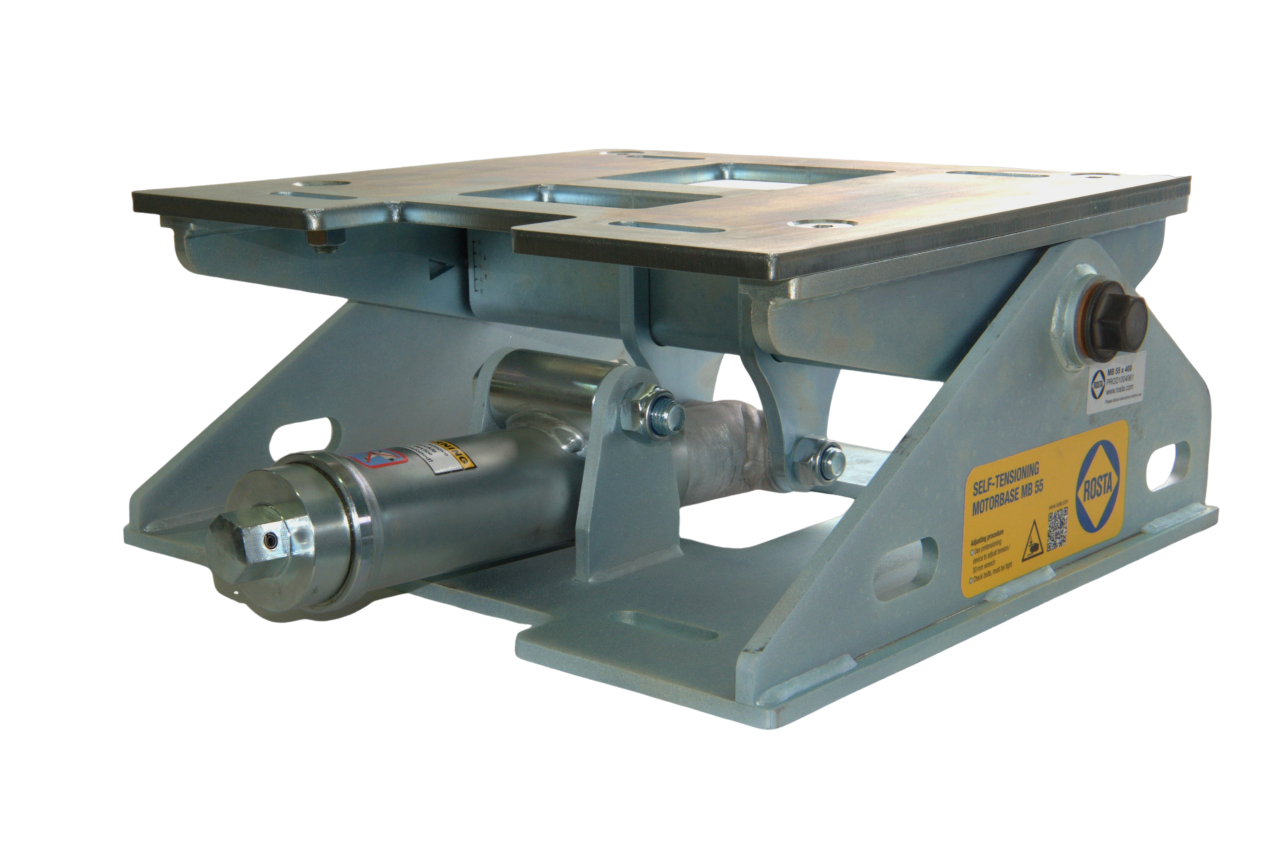

Type MB 55

The new ROSTA MB 55 Motorbase, for electric motors, includes a central pre-tensioning device, supports motor footprints on both plates, has an interchangeable motor plate for center or offset positions and comes in three sizes.

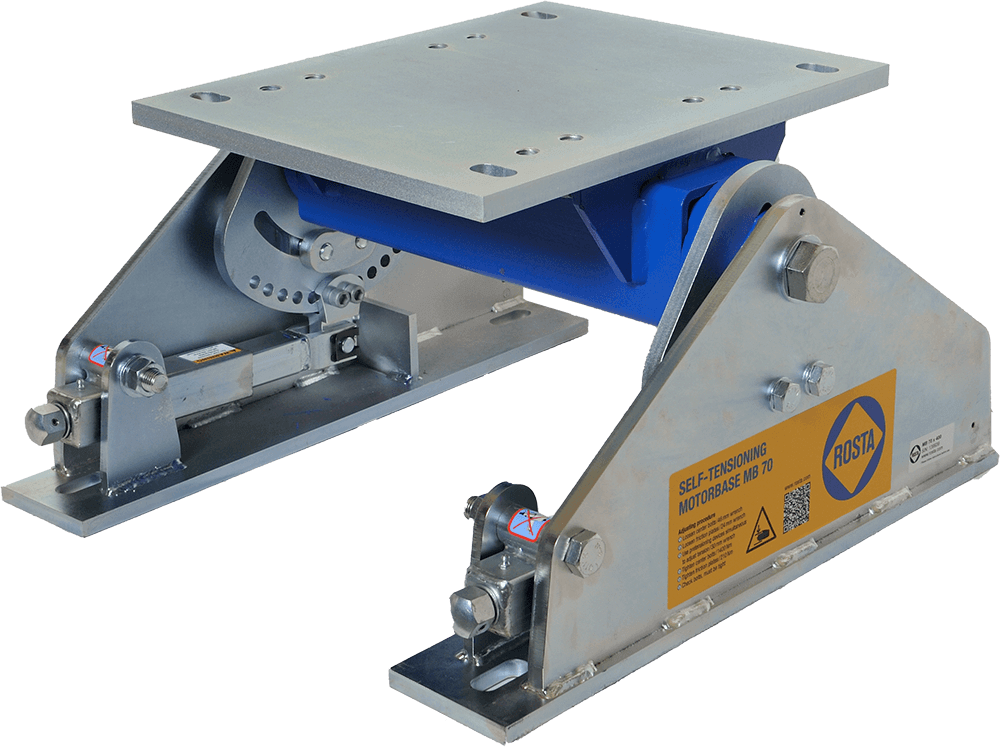

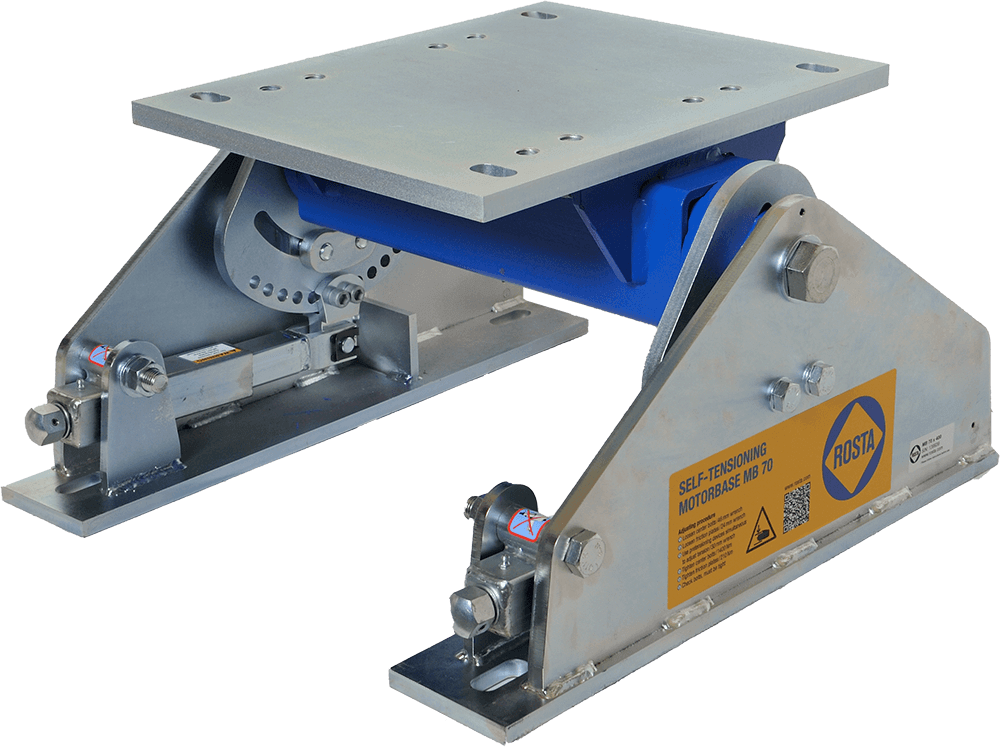

Type MB 70

The ideal standardized motor base for heavy duty belt drives with electric motors from 37 to 200 kW (frame 250 M to 315 S).

Type MB 75

The MB 75 features a single, centered pre-tensioning device for easy handling (like the MB100).

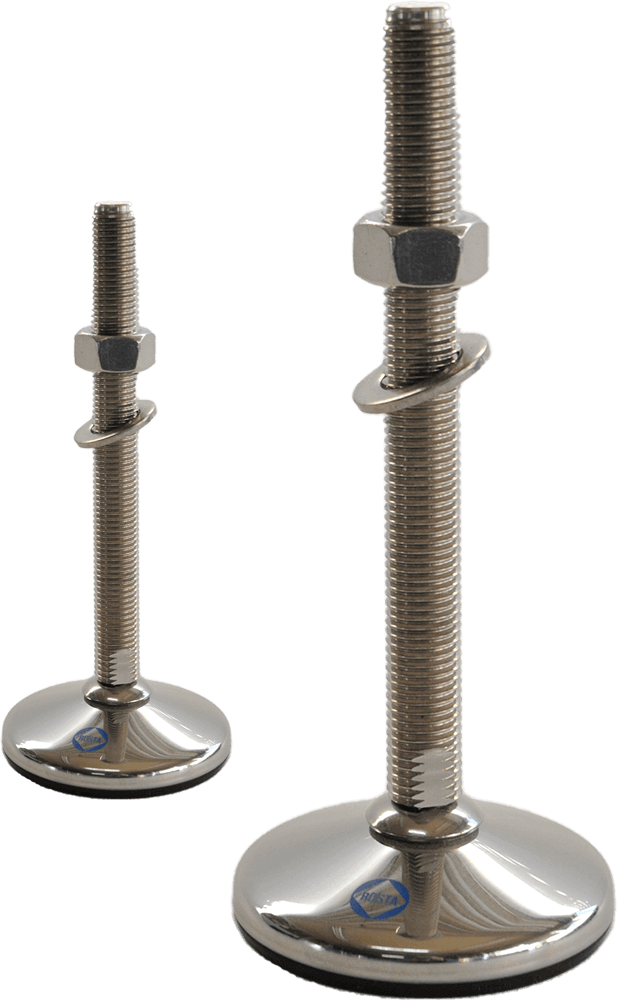

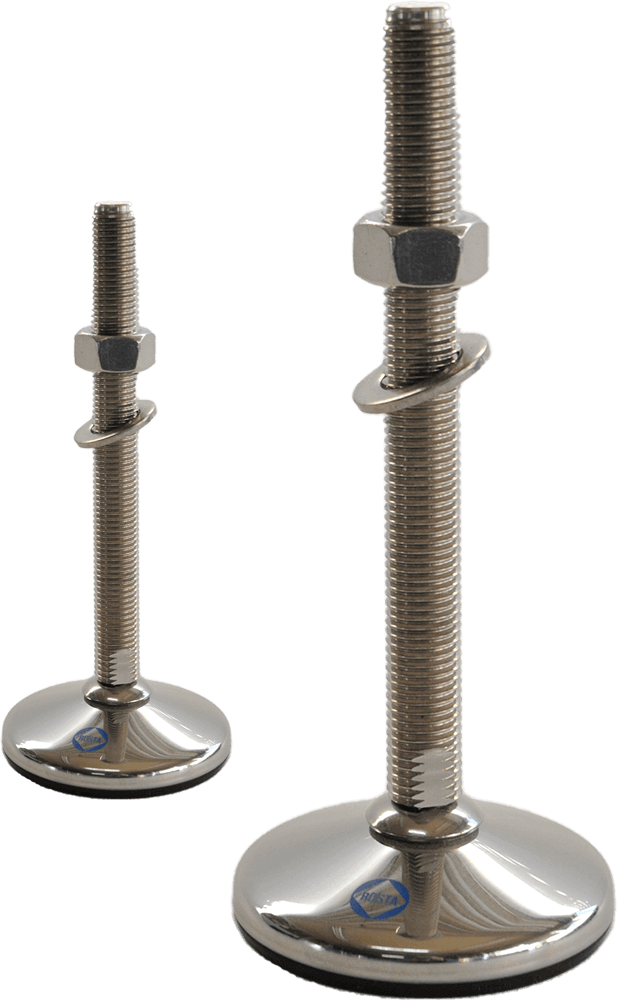

Type N

Machines, apparatus, installations only work as well as they stand!

Type NOX

Machines, apparatus, installations only work as well as they stand!

Type Roller R

The roller is made of high-quality industrial plastic material with two self-lubricating ball bearings 2Z.C3.

Type Roller RL

The tensioning roller is made of industrial plastic material with two self-lubricating ball bearings 2Z.C3 and is designed for light-duty drives.

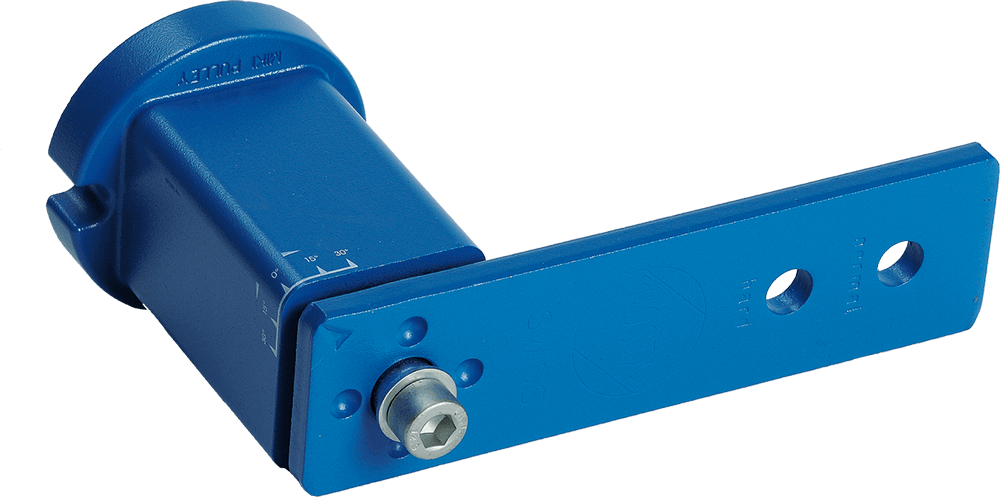

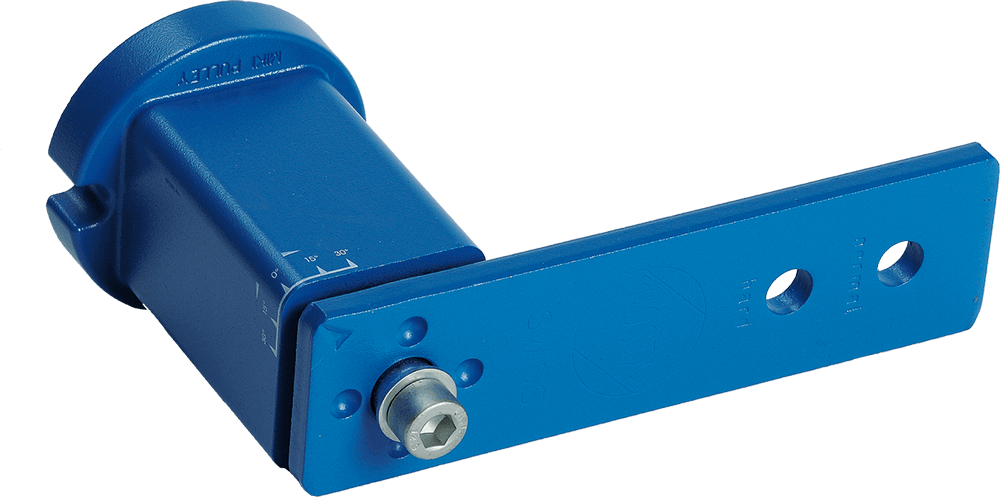

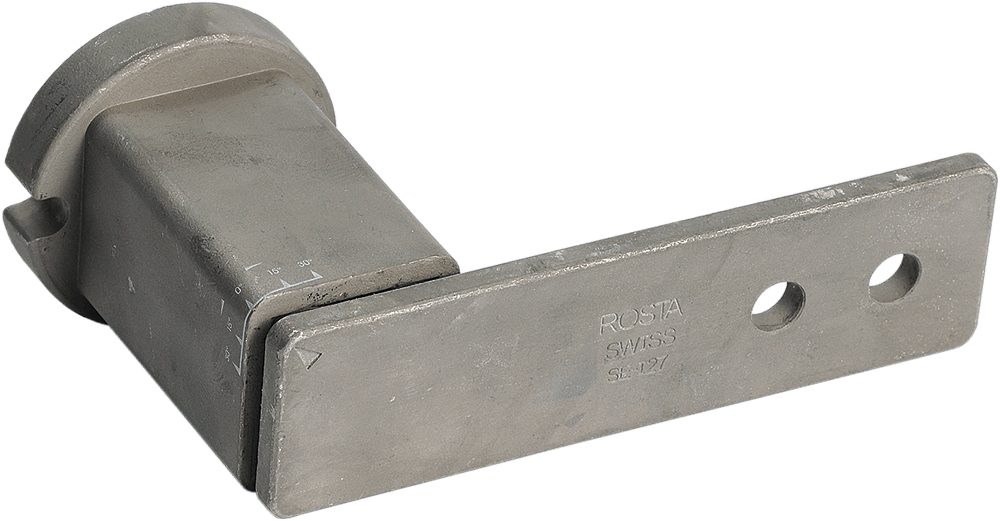

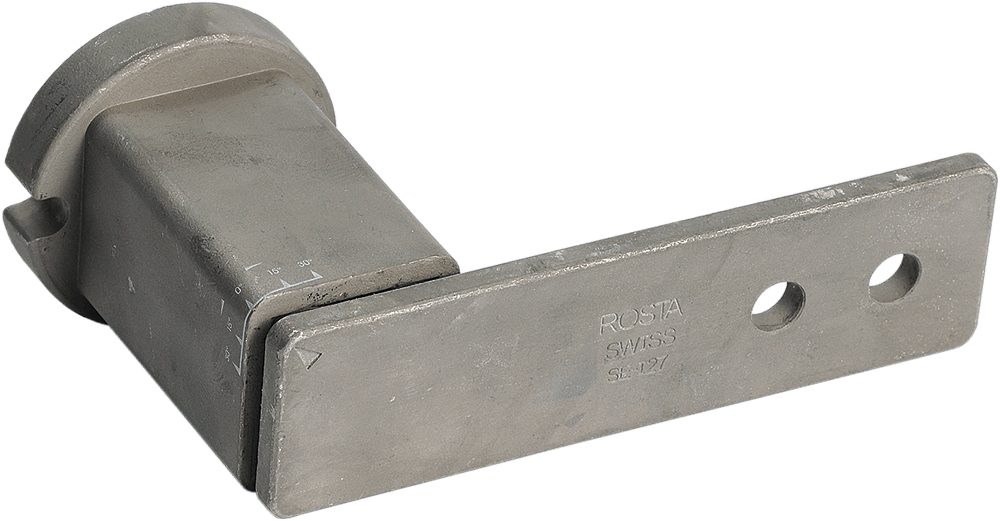

Type SE

The tensioning element with the specification SE (SE 11 to SE 50) is the most commonly used unit for tensioning all types of chain and belt drives.

Type SE-B

The ROSTA tensioning element type SE-B (Boomerang) compensates the slack in extremely long chain drives.

Type SE-F

The ROSTA tensioning elements type SE-F is designed for front mounting applications on "blind" frame structures.

Type SE-FE

The ROSTA tensioning element type SE-FE is designed for front mounting applications on engines such as cooling compressors and fan drives.

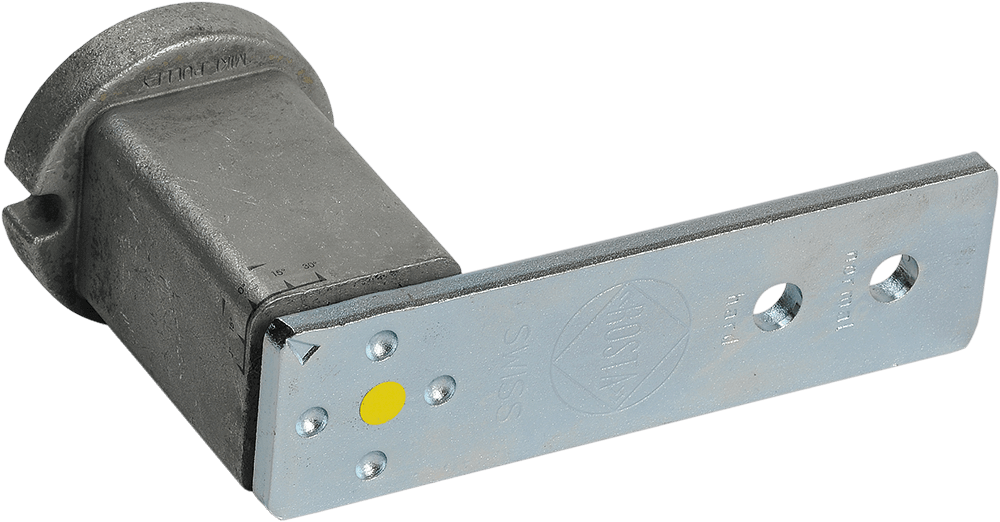

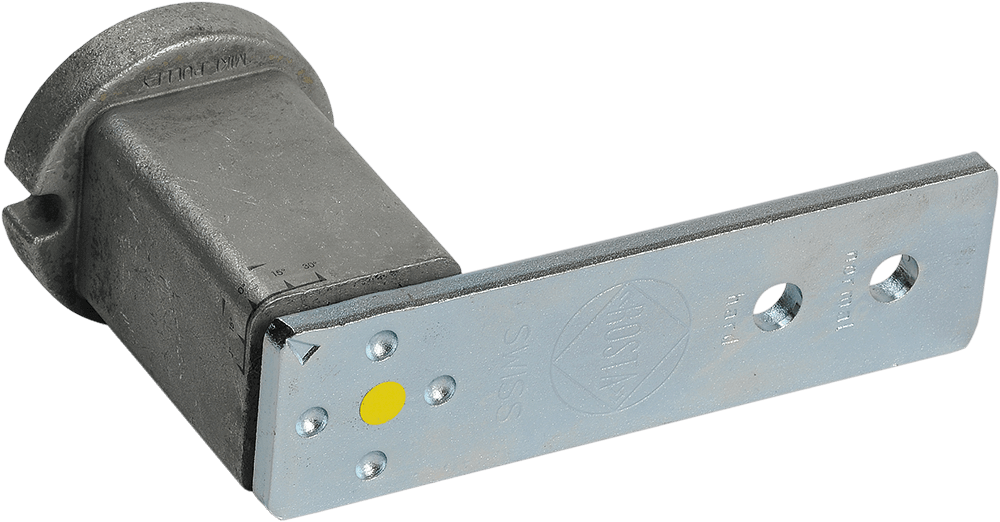

Type SE-G

The tensioning element type SE-G (marked with yellow dot) has zinc-plated steel parts and therefore is specially designed for "outdoor" applications; e.g. for building machines.

Type SE-I

The ROSTA tensioning elements type SEI are all made out of stainless steel.

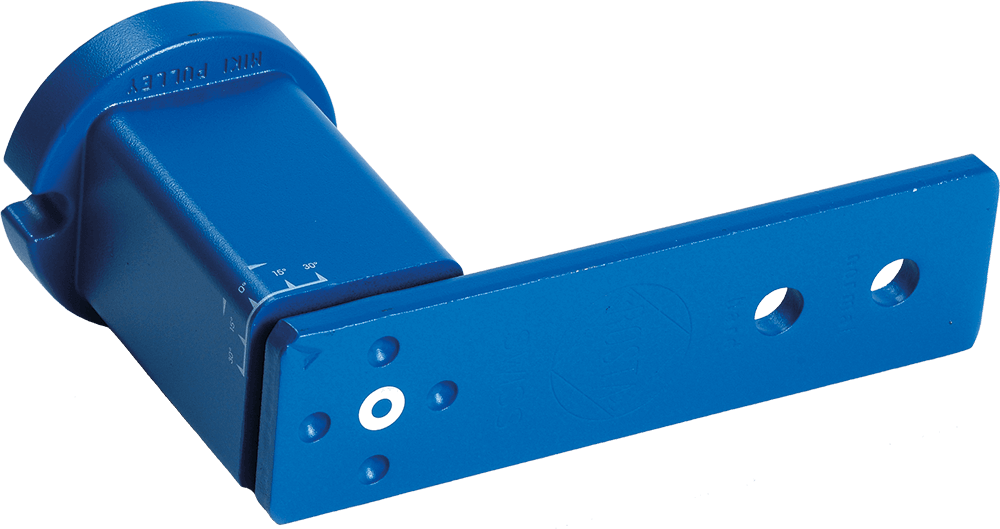

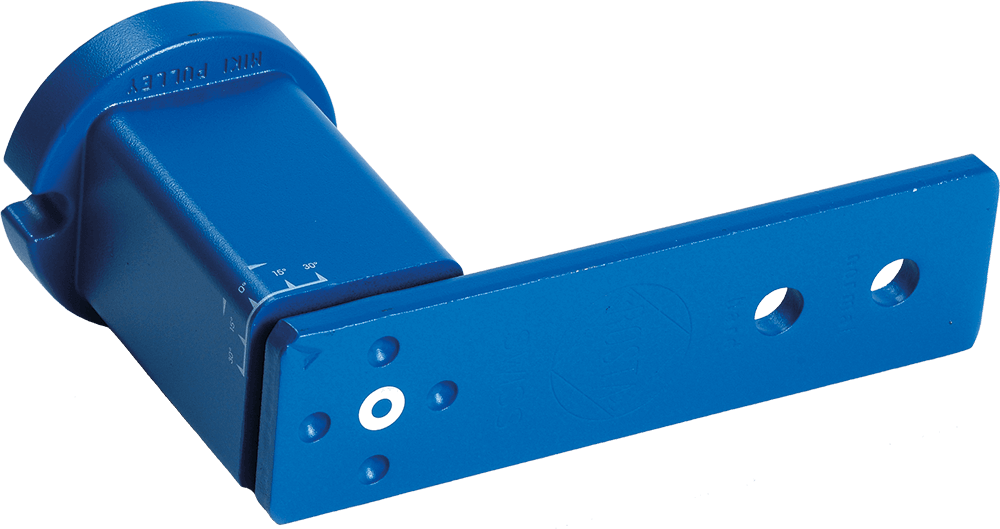

Type SE-R

Tensioning element with strengthened tensioning arm.

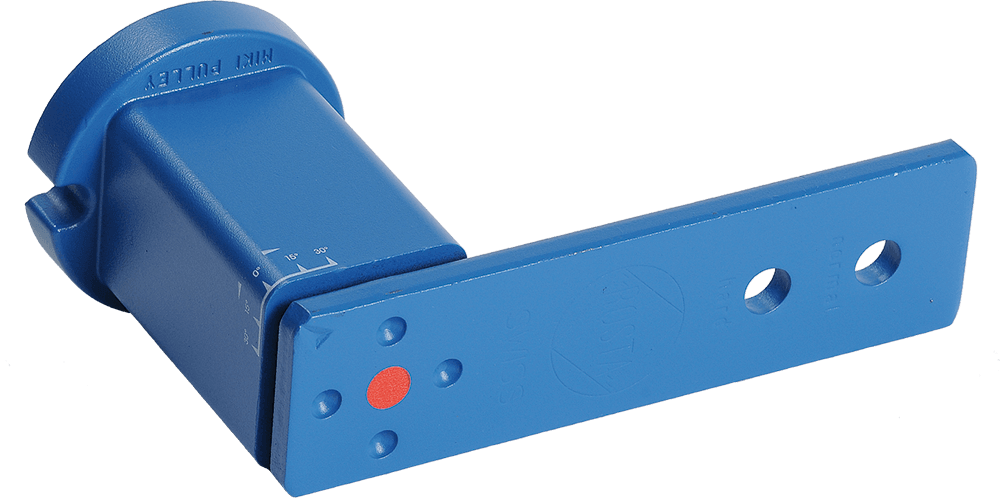

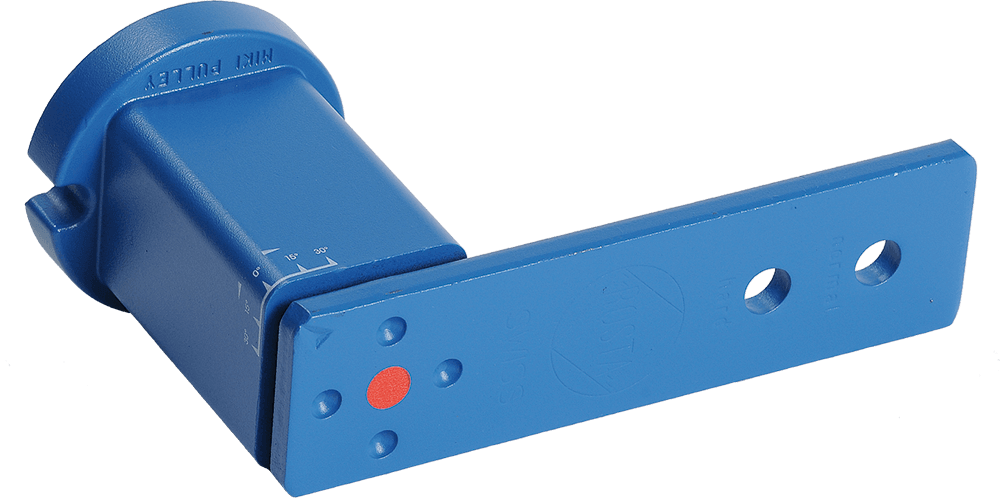

Type SE-W

The tensioning element type SE-W (marked with red dot) is equipped with heat resistant elastomeric inserts.

Type ST

ROSTA oscillating drive heads type ST are flexible joints transmitting the acceleration forces.

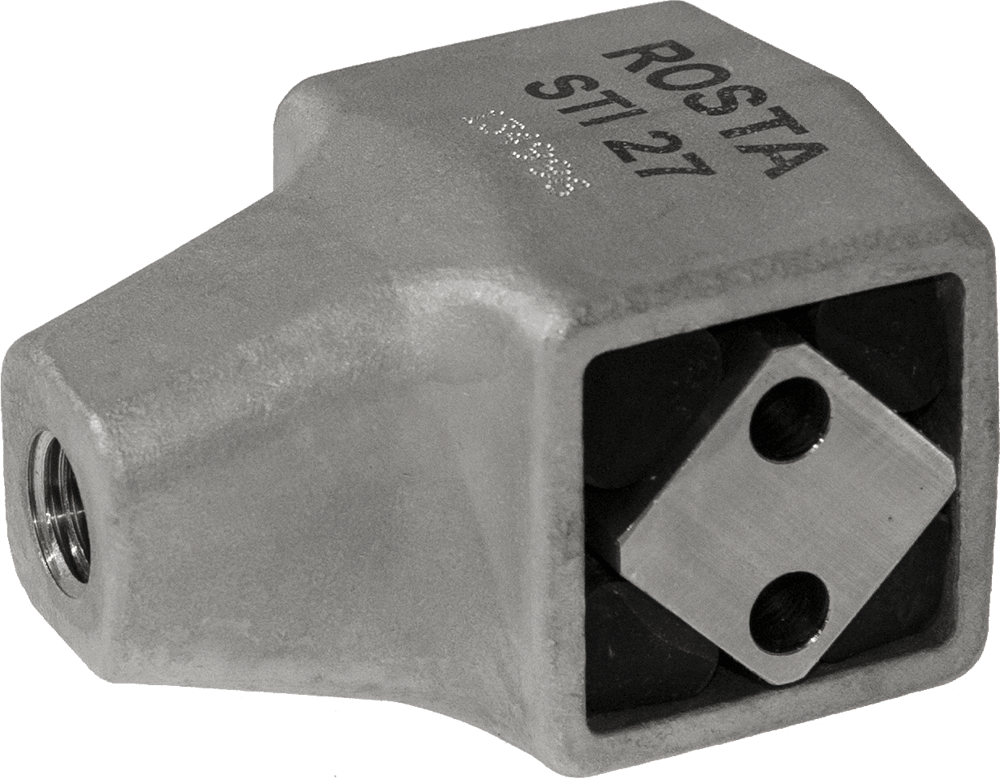

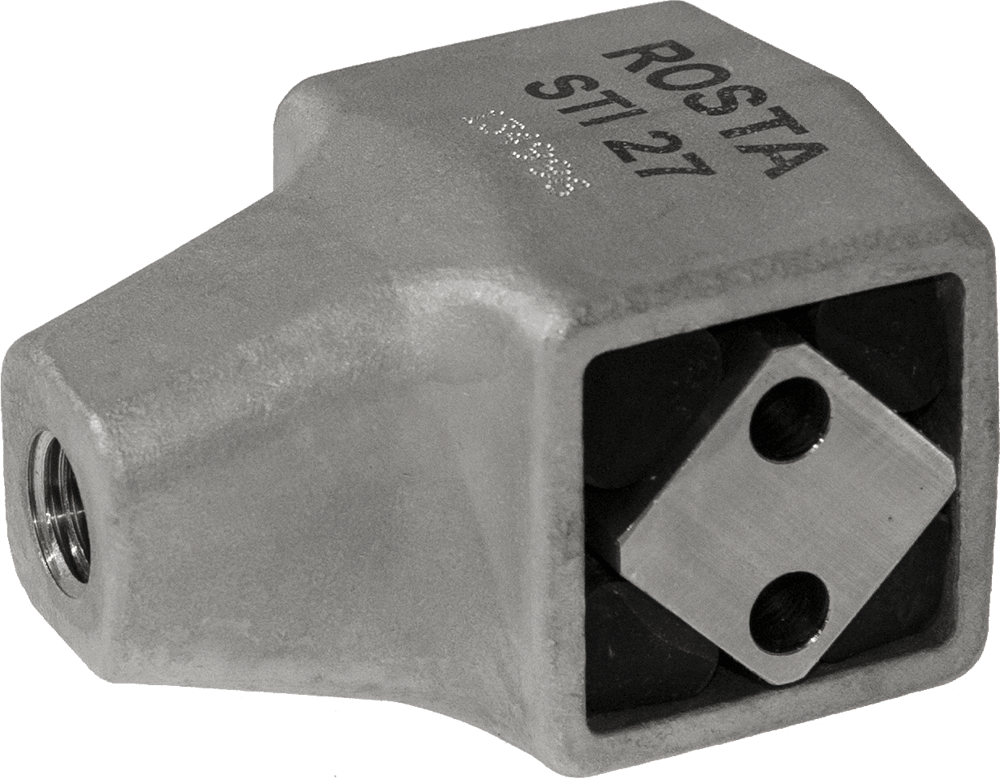

Type STI

ROSTA oscillating drive heads type STI are flexible joints transmitting the acceleration forces.

Type V

ROSTA anti-vibration mounts type V are multi-directional dampers and are designed to accept compression, tension and shear loading as well as combined loadings.

Type Wheel N

The sprocket wheel runs on a self-lubricating ball bearing 2Z.C3.

Type Wheel set - type N

The ROSTA sprocket wheel set completes the tensioning element for applications in chain drives.

Type WS

ROSTA modules should be connected on machine parts/structures by means of the standardized clamps and brackets.

Explore ROSTA

We support our customers to choose the appropriate ROSTA element.

about

Today, ROSTA AG exports over 90% of its products. With six subsidiaries and over 35 distribution partners worldwide, there is certainly one in your region. With a clear grow strategy, ROSTA is expanding on all levels.

contact us

Get in touch with us. Find your ROSTA company or the ROSTA distribution partner in your country nearest to you and let us know how we can support you to make you successful in your market.