Any chain drive requires a tensioning system to compensate for elongation and ensure smooth and quiet operation. Without adequate tensioning, Chain drives are susceptible to increased wear and premature failure. Automatic tensioning optimises chain drive performance and lifespan.

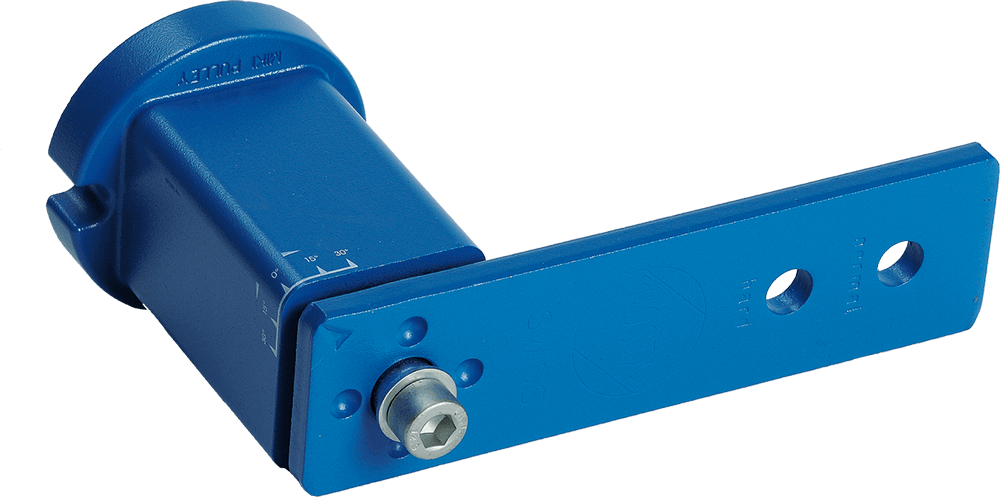

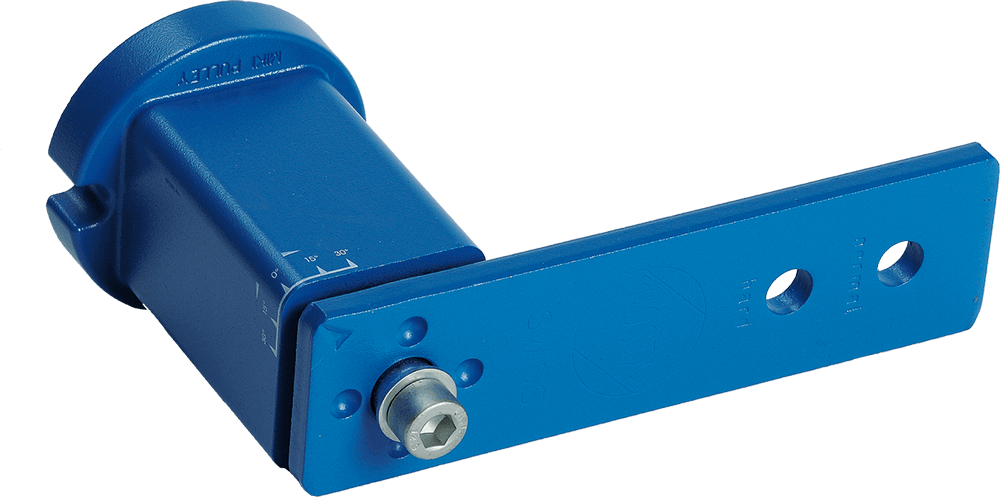

ROSTA SE tensioners and accessories provide you with a simple to install solution which continuously applies tensioning force to the chain drive without the need for manual adjustment, and as with all ROSTA products with zero maintenance.

Download our product catalogue for technical product information, an in-depth technology overview and more, or get in touch with our sales department to have a consultation on how ROSTA can help you.

Chain Standard

Chain Size

Idler Type

| ROSTA SE Tensioner | ROSTA Chain Idler |

|---|---|

| SE 38 | N1" - 20 D |

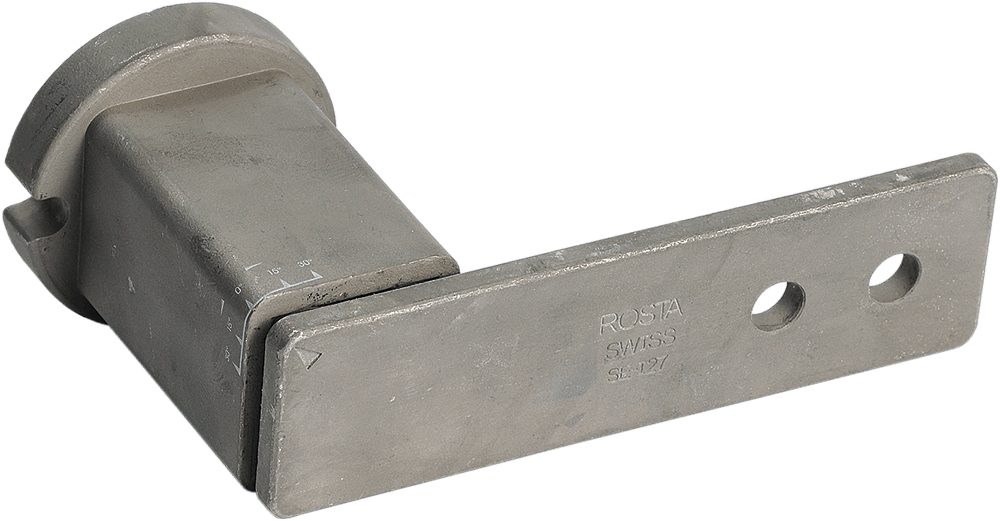

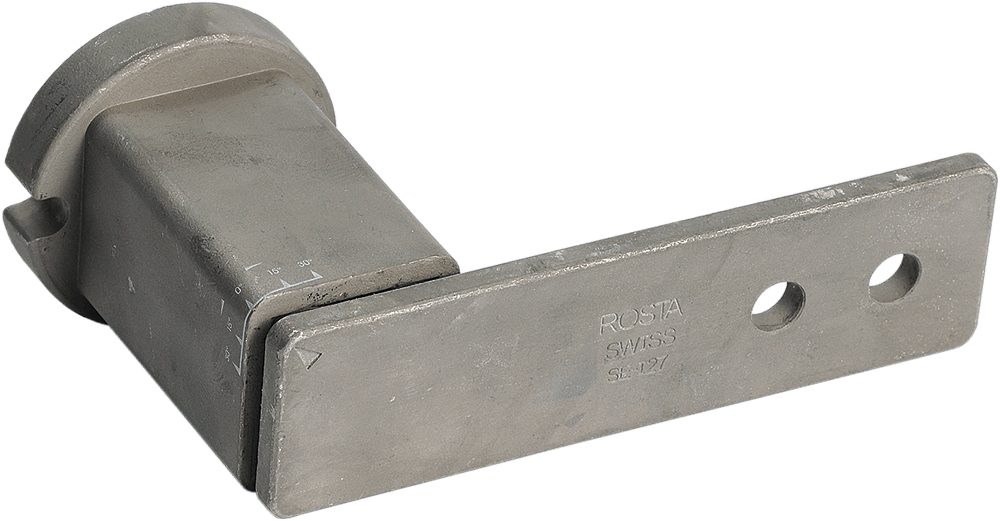

The tensioning element with the specification SE (SE 11 to SE 50) is the most commonly used unit for tensioning all types of chain and belt drives.

The ROSTA tensioning element type SE-B (Boomerang) compensates the slack in extremely long chain drives.

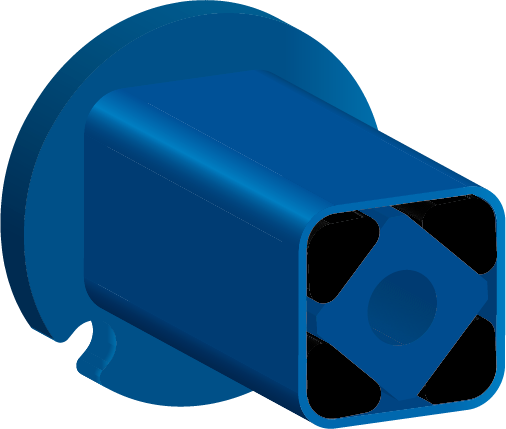

The ROSTA tensioning elements type SE-F is designed for front mounting applications on "blind" frame structures.

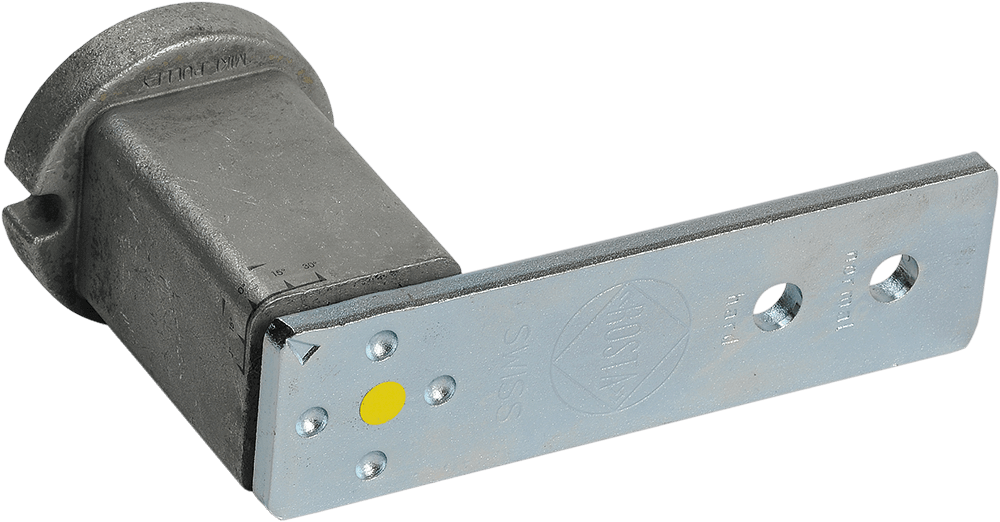

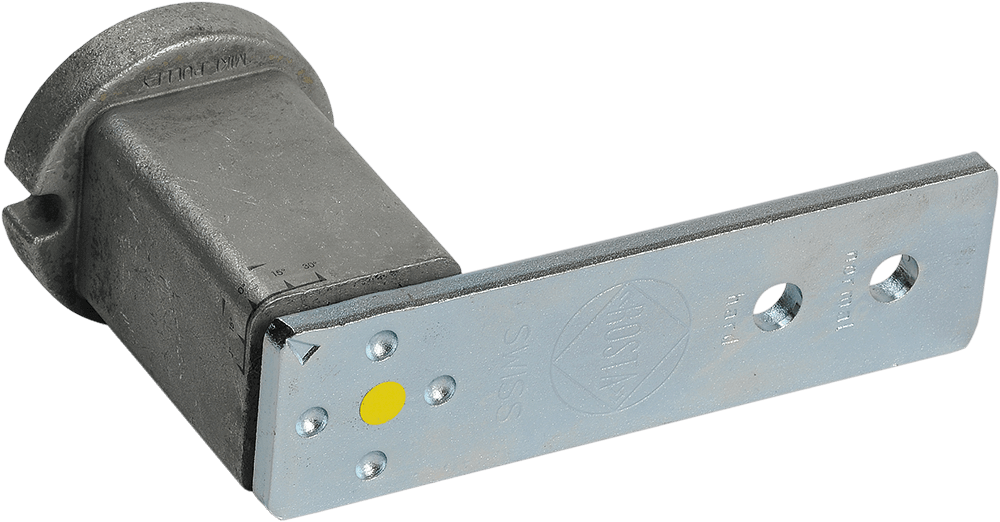

The tensioning element type SE-G (marked with yellow dot) has zinc-plated steel parts and therefore is specially designed for "outdoor" applications; e.g. for building machines.

The ROSTA tensioning elements type SEI are all made out of stainless steel.

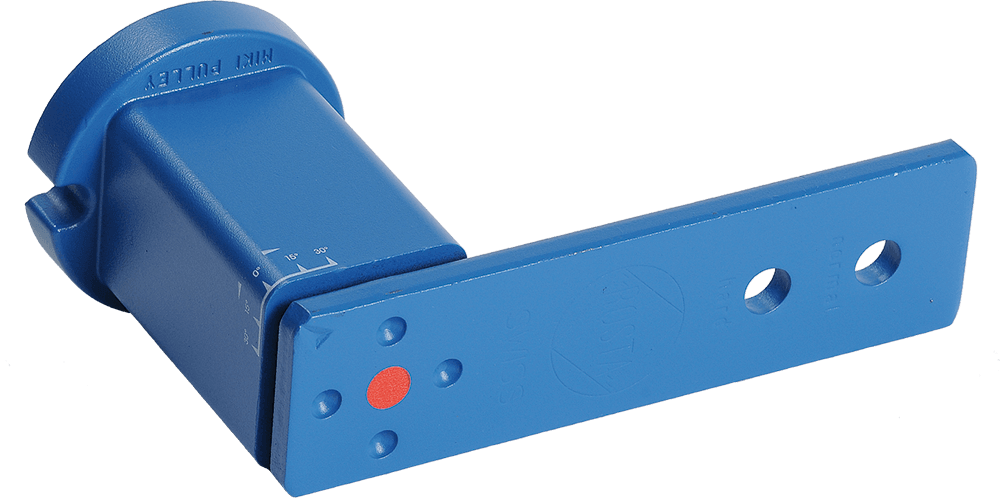

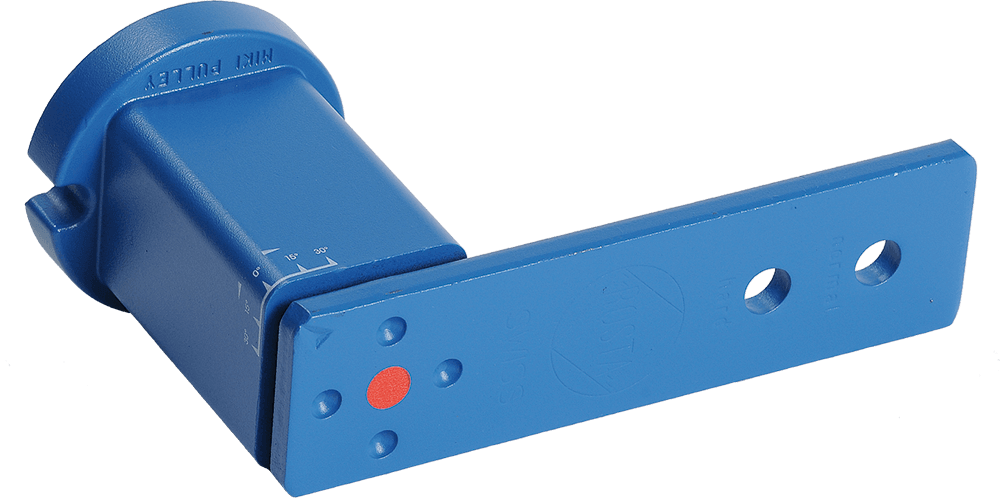

The tensioning element type SE-W (marked with red dot) is equipped with heat resistant elastomeric inserts.

Many companies worldwide value our products and recommend them to others. But read for yourself what our customers have to say about their experiences with us.

The ROSTA Element, an elastomer powered torsional spring, is central to our range of specialized machine components designed to provide a combination of useful functions. ROSTA components offer dependable performance across a broad spectrum of industrial applications

Select ROSTA elements are capable of being refurbished by replacing either the rubber cords, the inner mounting or the outer housing. Not only is this efficient, but its great for the environment as well.

Contact Sales to learn more about our refurbishment options.

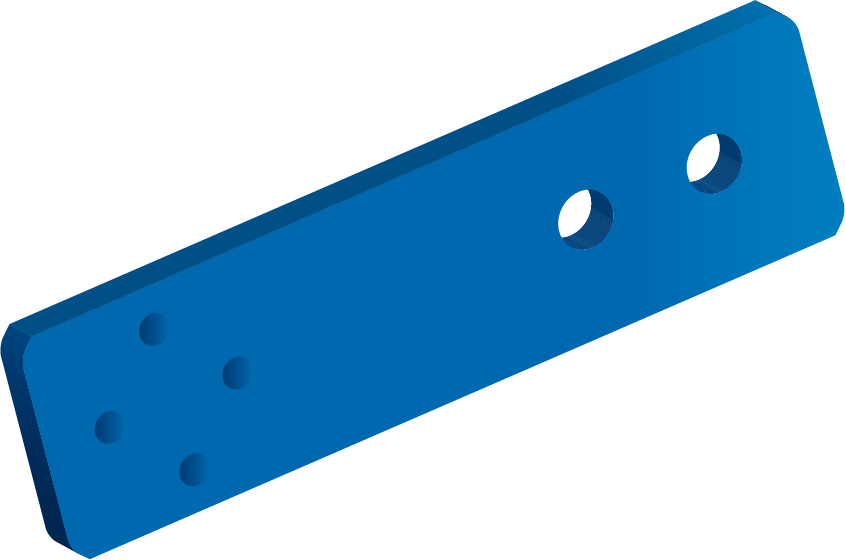

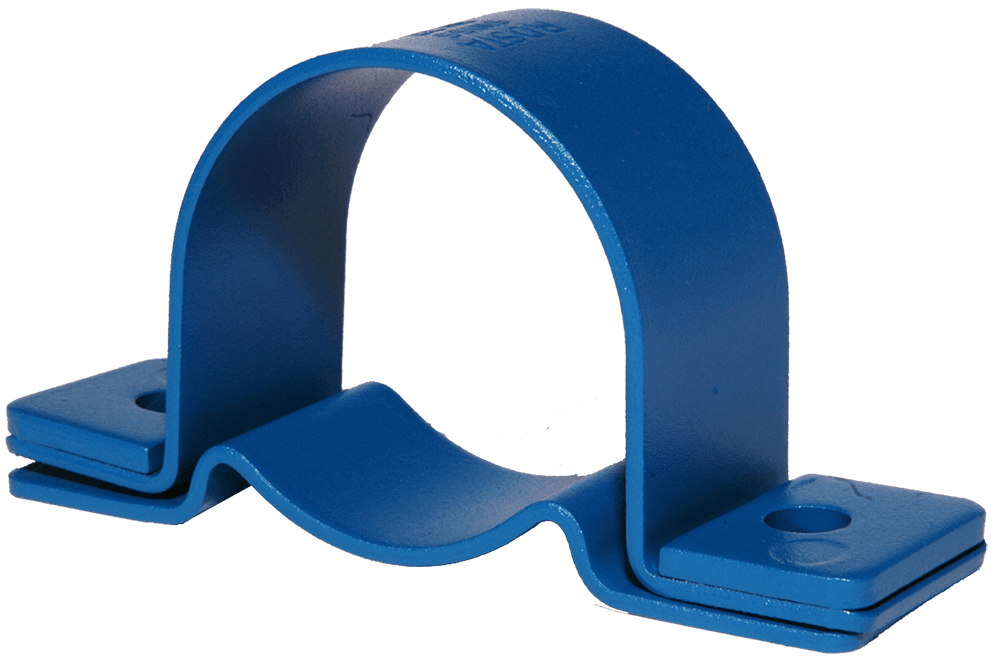

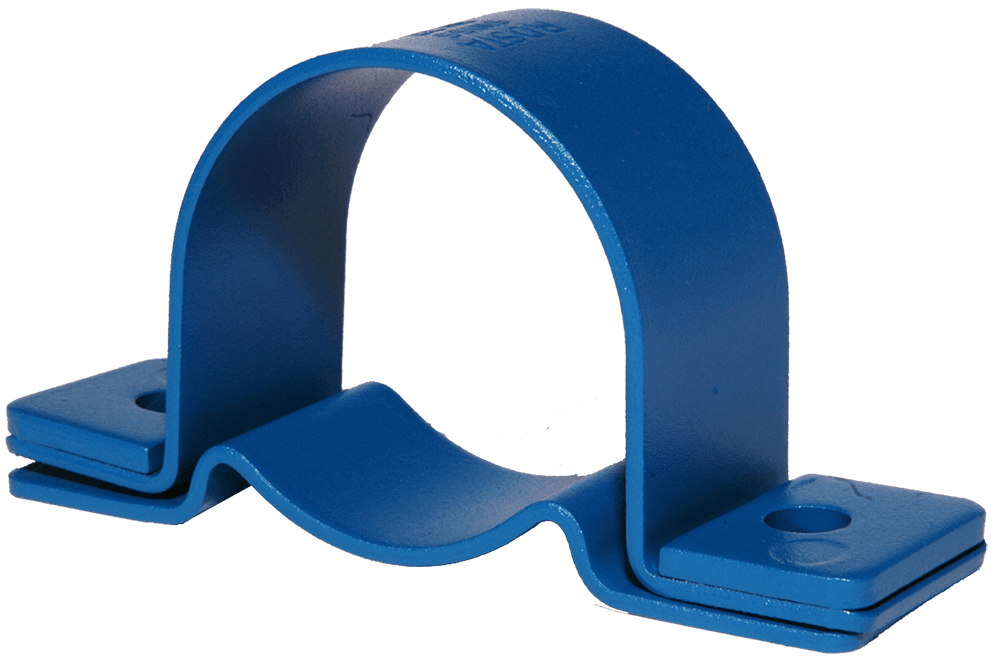

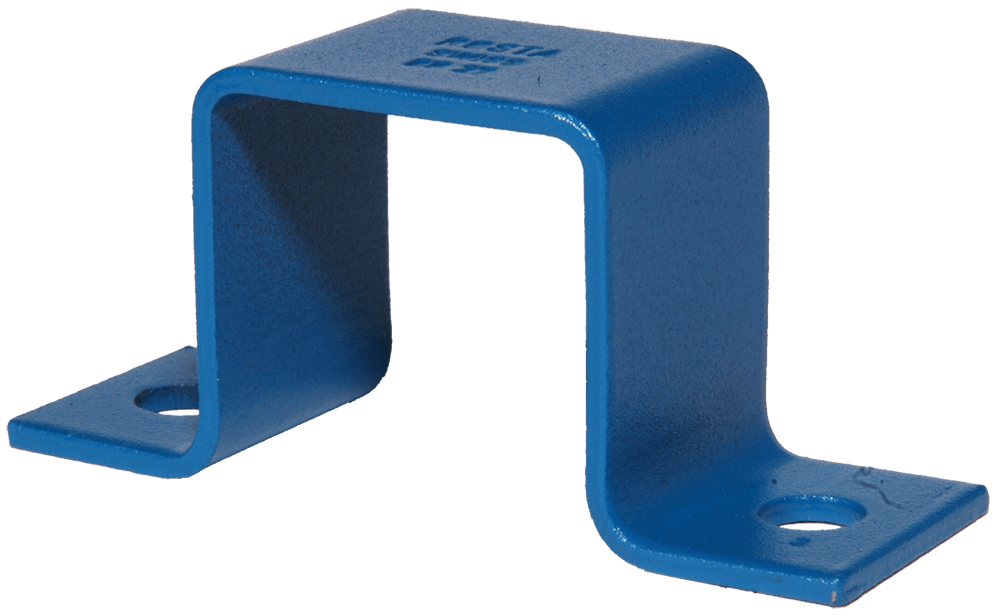

ROSTA modules should be connected on machine parts/structures by means of the standardized clamps and brackets.

ROSTA modules should be connected on machine parts/structures by means of the standardized clamps and brackets.

This high-quality rider is made of friction resistant industrial plastic and allows the use on both rider sides.

The high-quality rider is made of friction resistant industrial plastic and allows the use on both rider sides.

The roller is made of high-quality industrial plastic material with two self-lubricating ball bearings 2Z.C3.

The tensioning roller is made of industrial plastic material with two self-lubricating ball bearings 2Z.C3 and is designed for light-duty drives.

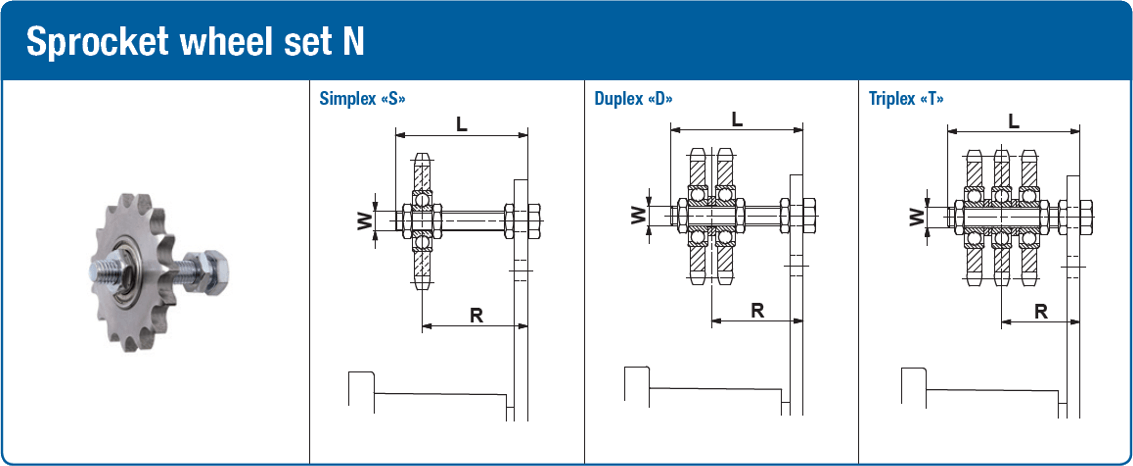

The sprocket wheel runs on a self-lubricating ball bearing 2Z.C3.

The ROSTA sprocket wheel set completes the tensioning element for applications in chain drives.

ROSTA modules should be connected on machine parts/structures by means of the standardized clamps and brackets.

Elastic suspension for all types of screening machines and shaking conveyors. ROSTA offers the widest range of oscillating mountings. From standard mounts to heavy duty. Also available in stainless steel.

Get in touch with us. Find your ROSTA company or the ROSTA distribution partner in your country nearest to you and let us know how we can support you to make you successful in your market.